A fuse is a one type of low resistance resistor that acts as a sacrificial device to provide over current protection of either the load or source circuit.

- Its important component is a metal wire or strip that melts when too much current flows through it, interrupting the circuit that it connects. Fuses are an alternative to circuit breakers.

- High current flowing through thin fuse wire raises its temperature causing it to melt and thereby trips the circuit breaker and prevents currents reaching excessive value which will damage essential component.

- The melting point depends upon type of material used copper wire fuse melts at 1060 ‘C , Silver tungsten fuse melts at 960’C .

- The size of wire is so chosen that it allows normal current to pass through it without causing overheating.

- A fuse generally consists of of a metal strip and fuse wire of small cross-section compared to the circuit conductors, mounted between a pair of electrical terminals and (usually) enclosed by a non-combustible housing.

- Minimum fusing current, is that current at which will cause it melt.

- Current rating is the normal current that can be carried continuously without overheating.

- Time/current characteristics are obtained by testing six or more same type of fuses and plotting the results.

- Minimum test current is 1.05 times the minimum fusing current.

- Maximum test current is that which will cause it to melt in less than 0.5 sec. Rest all other test currents are equally spaced between these currents.

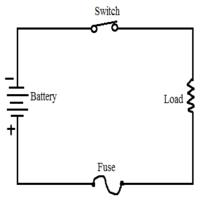

- Fuses are arranged in series to provide or pass full current through the protected circuit.

- Fuses element are made up of silver, aluminium, copper, in which provide stable and predictable time/current characteristics.

- Fusible element surrounded by air or other material that provide quenching of arc. E.g. silica sand.

Working Principle of Fuse

The principle on which fuse works is “heating consequence of the current”. It is fabricated with a lean strip or thread of metallic wire. The connection of the Fuse in an electrical circuit is always in series. When too much current is produced due to the heavy flow of current in the electrical circuit, the fuse gets soften and it opens the circuit. The extreme flow of current may direct to the collapse of the wire and prevents the supply.

The fuse can be changed by the new fuse with an appropriate rating. It can be designed with the elements like Cu (copper), Zn (zinc), Al (aluminum) and Ag (silver).

Fuse rating = (power (watts)/voltage (volts)) x 1.25

The selection of a fuse can be done by calculating the fuse rating by using the above formula.

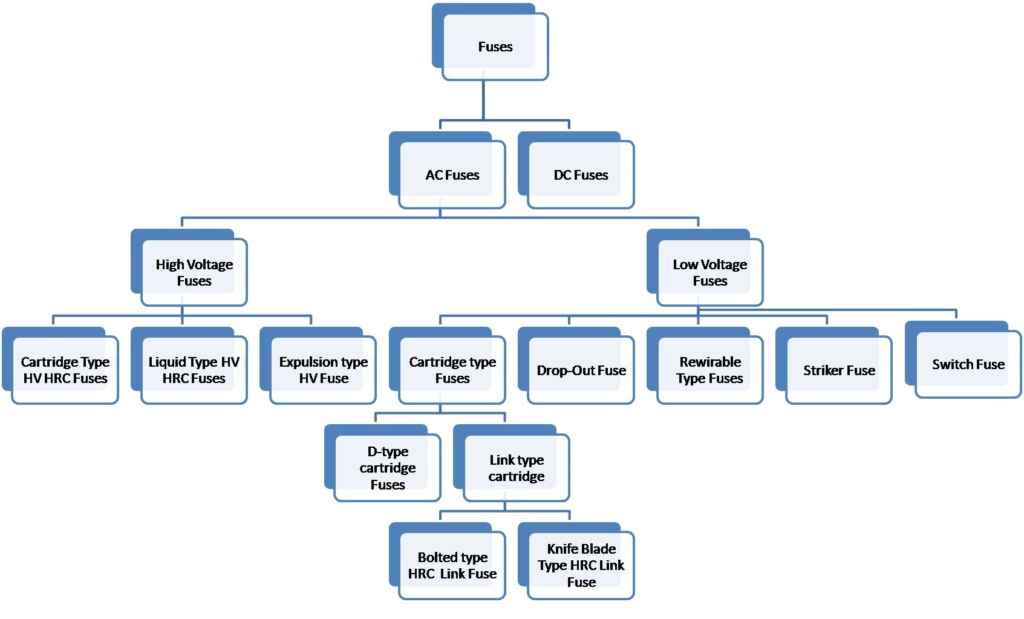

Different Types of Fuses

The fuses are classified into different types based on the application namely AC type fuse and DC type fuse. Again these fuses are classified into several types. The following diagram shows the electrical fuse types chart based on the AC fuse and DC fuse.

High Rupturing Capacity (HRC) Fuse

- HRC fuse consists of a fuse wire in it, which carries the short circuit current safely for a given time period. During this time period, if fault is withdrawn, then it will break otherwise it will melt and remove the circuit from electrical supply hence, the circuit remains safe.

- HRC fuse consists of highly heat resistant materials body having metal end caps, which is welded by silver current carrying element (silver wire)

- The fuse body internal space is fully packed with a filling powder. That’s why it carries normal current without overheating.

Advantages

- Stable time/current characteristics.

- Reliable for discrimination.

- No chances of smoke or fire.

- Deteriotion is negligible.

- Cartridges are so sized that only connect value fuse can be filled.

- Used for very high faults levels.

- Having high speed operation.

- Require no maintenance.

- Cheaper.

Disadvantages

- After each operation, they have to be changed.

- Heat produced by the arc may affect the other switches.

- Environment hazard.

- Arcing when this type of fuse melts is buried in the powder fusion of which in path provides quenching and helps to extinguish it.

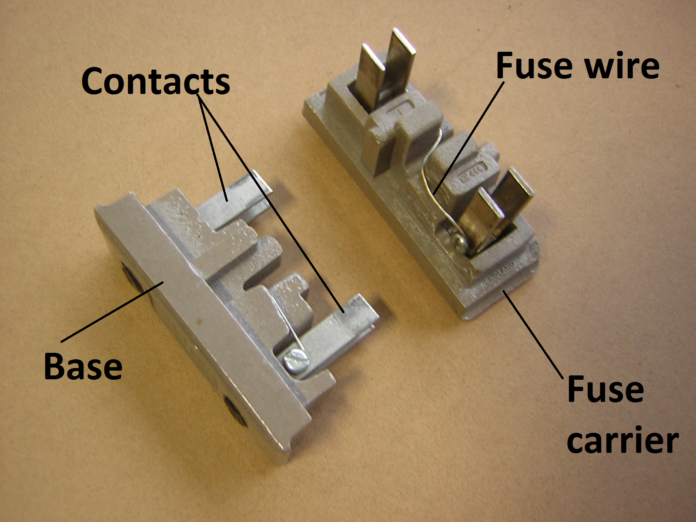

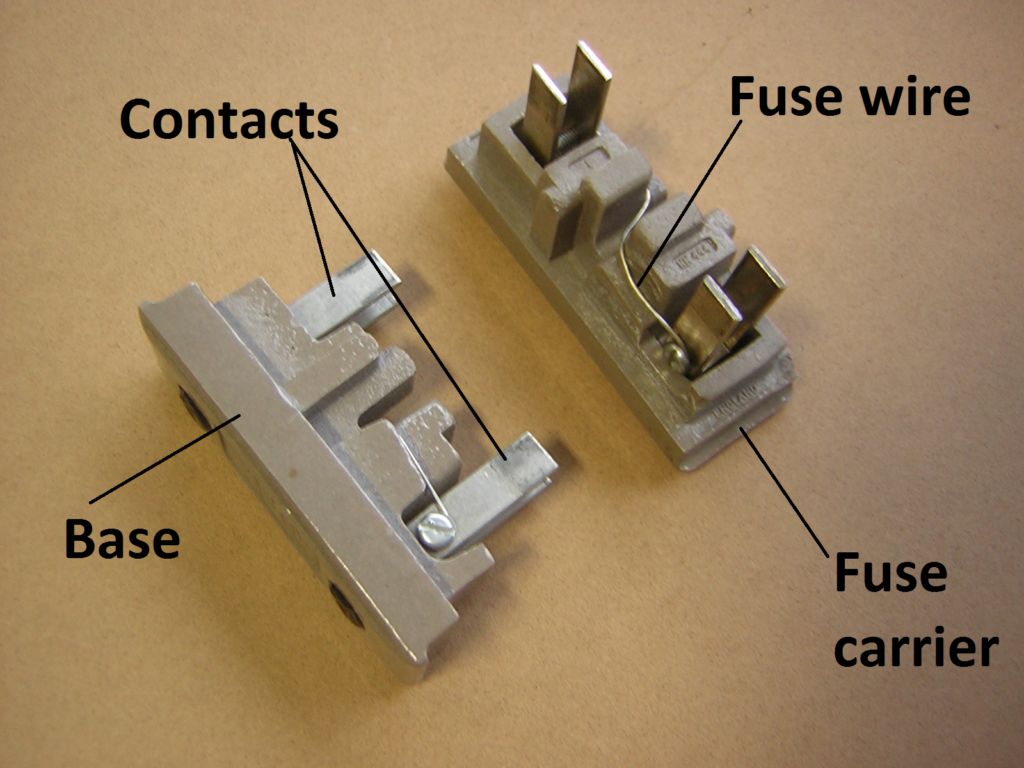

Semi-enclosed fuse or Rewireable fuse

These have insulated carrier for safe handling and are enclosed in asbestos lined tube.

Wire are easily replaced after operation.

Design is subjected to abuse. As thicken wire can be used which could mask the fault and cause arcing if it does not operate. Another fault is the premature failure if thinner wire used due to oxidation or contact with air or being stretched while being filled.