Q. a) One of the objectives of UNCLOS is protection of marine environment and prevention of pollution. Define pollution as per UNCLOS and discuss the key features of obligations of coastal states in this regard.

b) State the 3 main tiers of oil pollution damage compensation conventions of the IMO. In each case elaborate on WHO is responsible for payment of compensation. Also state the source of the funds as well as certification required by the ship under each tier.

Answer:-

a). “Pollution of the marine environment” means the introduction by the man, directly or indirectly, of substances or energy into marine environment, including estuaries, which results or is likely to result in such deleterious effects as harm to the living resources & marine life, dangerous to human health, hindrance to marine activities, including fishing & other legitimate uses of the sea, degradation of quality for use of sea water & reduction of the amenities.

Obligations of the Coastal States

PART XII. PROTECTION AND PRESERVATION OF THE MARINE ENVIRONMENT

Article -192: States have obligations to protect & preserve the marine environment.

Article -193: States have the sovereign right to utilize their natural resources ( pursuant to their environmental policies & in compliance with their duty to protect & preserve the marine environment).

Article – 194: States shall take, individually or jointly as suitable, all measures consistent with this Convention that are rewquired to prevent, reduce & control pollution of the marine environment from any source.

(States shall assure that activities under their jurisdiction or control are so conducted as not to cause damage by pollution to other States & their environment.

The action taken pursuant to this Part shall deal with all sources of the pollution of the marine environment.

(a) The emission of toxic, harmful or the noxious substances, generally those which are persistent, from land-based sources, from or through the atmosphere or by dumping.

(b) Pollution from the vessels, in particular measures for preventing accidents & dealing with emergencies, assuring the safety of operations at sea.

(c) Pollution from installations & devices used in exploration or exploitation of the natural resources of the seabed & subsoil, in particular measures for preventing accidents & dealing with emergencies, assuring the safety of operations at sea).

Article – 195: Duty not to transfer damage or transform one type of pollution to another.

(States shall act so as not to transfer, directly or indirectly, damage from one area to another or change one type of pollution into another).

Article -196: States shall take all action required to prevent, reduce & control pollution of the marine environment resulting from the use of the technologies. (Use of the technologies or introduction of an alien or new species)

(b).

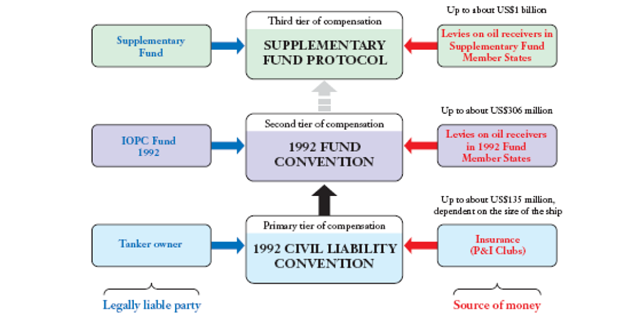

First layer of compensation:-

The Tanker Owner & his Protection & Indemnity Association (P&I Club)

- The 1992 CLC covers pollution damage suffered in the territory or territorial sea or Exclusive Economic Zone (EEZ) or equivalent area of a State party to the Convention. The flag State of the tanker and the nationality of the owner are irrelevant for determining the scope of application.

- For both laden and un laden tankers

- CLC based on strict liability: Whoever fault the owner is liable

- Claims can only be made against the registered owner or his insurer

- Owners of tankers carrying more than 2,000 tonnes of persistent oil in bulk as cargo are required to maintain insurance or other financial security, and to carry on board each tanker a certificate attesting to the fact that such insurance cover is in force.

- Most tanker owners arrange oil pollution insurance with a Protection and Indemnity Association (P&I Club). Under the 1992 CLC, claims for the pollution damage (including clean-up costs) for which the tanker owner would be responsible may be brought directly against the insurer or provider of the financial security.

The 2000 Amendments

Adoption: 18 October 2000

Entry into force: 1 November 2003

- The amendments raised the compensation limits by 50 percent compared to the limits set in the 1992 Protocol, as follows:

- For a ship not exceeding 5,000 gross tonnage, liability is limited to 4.51 million SDR

- For a ship 5,000 to 140,000 gross tonnage: liability is limited to 4.51 million SDR plus 631 SDR for each additional gross tonne over 5,000

- For a ship over 140,000 gross tonnage: liability is limited to 89.77 million SDR

- For CLC: 4.51 Million SDR to 89.77 Million SDR

Second Layer Of Compensation—The 1992 Fund

Note: The 1992 Fund will not pay compensation if the damage occurred in a State which was not a Member of the 1992 Fund

- Any country which imports 1, 50,000 tonnes per annum will have to contribute towards FUND. This FUND is managed by an independent Director appointed by IMO. The Fund’s obligation to pay compensation is confined to pollution damage suffered in the territories including the territorial sea of the Contracting States. The Fund is also obliged to pay compensation in respect of actions taken by a Contracting State outside its territory.

- For a single incident the maximum the amount payable including the contribution from CLC is 203 million SDR

- If three states import more than 600 million tons of oil per annum are involved in an incident then the maximum compensation payable is 300.74 million SDR including the contribution from CLC.

Third layer of compensation— the Supplementary Fund

- The 2003 Supplementary Fund is also financed by contributions payable by oil receivers in the States which ratify this new Protocol which is optional. But, there are 2 differences to the system that follows in the case of the 1992 Fund Convention. First, for the purpose of the contributions it is assumed that there is a minimum quantity of 1 million tones of contributing oil received in each of the Member State of the Supplementary Fund. Secondly, the Protocol includes a provision for the so-called ‘capping’ so that the aggregate amount of the contributions payable in respect of the contributing oil received in any single State in a calendar year should not exceed 20% of the total contributions levied. This is a temporary action till the total amount of contributing oil received in States which are party to the Supplementary Fund reaches 1,000 million tonnes or for a period of the 10 years from the date of entry into force, whichever is the earlier.

- As per 2003 Protocol of FUND convention, for any single incident the maximum compensation payable has been increased to 750 Million SDR including the contribution from CLC.

Voluntary Funds: (By P&I + Tanker Owners)

STOPIA (Small Tanker oil pollution indemnification Agreement)

TOPIA (Tanker Oil Pollution indemnification Agreement)

Taking into account the past disproportionate financial burden on the oil industry in respect of small ships, and recognizing that the Supplementary Fund increases the financial exposure of oil receivers in some States, the International Group of P&I Clubs, with the support of ship-owners, has introduced two voluntary agreements that are now in force

- STOPIA increases the financial exposure of tanker owners in the states who ratify 1992 Fund, beyond their CLC limit, and

- STOPIA provides for an increase, on a voluntary basis, of the limitation amount for small tankers to 20 million SDR, and applies to ships of less than 29,548 GT insured by one of the members of the International Group of the P & I Clubs & reinsured by the Group’s pooling arrangement. The STOPIA provisions apply to pollution damage in any State for which the 1992 Fund Convention is in force.

- TOPIA further increases the financial exposure of the tanker owners in those states that ratify the Supplementary Fund Protocol,

- For TOPIA, Ship-owners will contribute 50% of the total costs of the compensation in respect of payments made by the Supplementary Fund. It applies to tank ships insured by one of the members of the International Group of the P & I Clubs.

- This helps to maintain an equitable sharing of the financial burden of oil spill compensation between tanker owners & oil cargo interests.

Bunker convention

International Convention On Civil Liability for Bunker Oil Pollution Damage 2001

- Enter into force 21 Nov 2008

- Modeled on the CLC 69

- Compensation amount not exceeding LLMC 76 limits

- Based on strict liability and Direct action(i.e clain brought directly against the insurer)

- Ships of 1000Gt and above to maintain Bunker Convention Blue Card and Related Insurance certificate.

- The P&I issuing the Blue card will by default want to include war risk insurance with separate limit for P&I liabilities for this indemnification.

- The Limit value of this is the proper value of the ship but not more than $100 Million.