1. REGULATORY REQUIREMENTS

1.1. From 1 January 2020, the limit for Sulphur in fuel oil used on board ships operating outside designated emission control areas (ECA) will be reduced from 3.5% to 0.50% m/m (mass by mass)

1.2. Below are the options for compliance with Sulphur limit under MARPOL Annex VI:

i) Use a compliant fuel oil with a Sulphur content that does not exceed 0.50%

ii) If exceeding 0.50%, use an approved equivalent method e.g. an Exhaust Gas Cleaning System (‘Scrubber’)

iii) Use an alternative fuel e.g. LNG, methanol

1.3. Carriage of non-compliant fuel oil for combustion purposes for propulsion or operation on board a ship will be prohibited from 1 March 2020, except for vessels which have been fitted with equivalent methods (Exhaust Gas Cleaning System – EGCS – ‘Scrubber’).

All engineers and operators of EGCS should keep in mind that when EGCS is in operation, maintaining emission standards & wash water discharge standards is a very crucial task. Not complying with required standards and improper recordkeeping, will be considered violation of Regulation 14 of the revised MARPOL Annex VI.

1.4. MAIN PARAMETERS FOR COMPLIANCE:

The main parameters for compliance with MARPOL Annex VI equivalent method of reducing SOx, are as follows:

a. SO2 / CO2 ratio.

b. pH,

c. PAH

d. Turbidity of the wash water overboard.

e. Nitrates (wash water analysis ashore)

Emission Parameter limit for exhaust gas.

| Fuel Oil Sulphur Content | Ratio – emission SO2 (ppm)/CO2 (%v) |

| 0.50% | 21.7 (Max. allowed) |

| 0.10% | 4.3 (Max. allowed) |

Wash water parameter limits.

| pH | 6.5 * |

| PAH | 50 μg/L above the inlet water PAH ** |

| Turbidity | 25 FNU above the inlet water turbidity |

FNU – Formazin Nephlometric Units

* pH discharge limit at the overboard monitoring position or as a minimum pH 6.5 at 4 Meter from the overboard discharge point with the ship in stationary position which can be by computational fluid dynamics (CFD) method and this should be approved by Administration.

** The 50 μg/L limit described above is normalized for a wash water flow rate through the EGC unit of 45 t/MWh where the MW refers to the MCR or 80% of the power rating of the fuel oil combustion unit. This limit would have to be adjusted upward for lower washwater flow rates per MWh, and vice-versa, according to the table below.

| Flow rate (t/MWh) | Discharge concentration limit (μg/L PAH equivalents) |

| 0-1 | 2250 |

| 2.5 | 900 |

| 5 | 450 |

| 11.25 | 200 |

| 22.5 | 100 |

| 45 | 50 |

| 90 | 25 |

Note -1

- For a 15-minute period in any 12-hour period, the continuous PAH concentration limit may exceed the limit described above by up to 100 %. This would allow for an abnormal startup of the EGC unit.

- Similarly, the 25 FNU unit for the turbidity is also not to exceed the value in comparison with the inlet value of the turbidity.

2.0 OPERATION AND MONITORING REQUIREMENTS

2.1. Whenever the scrubber is in use following must be continuously monitored and recorded in data monitoring system. At leastEighteen months data will be stored in the system. PSC, Class or any external authority can check this data during their visit to vessel.

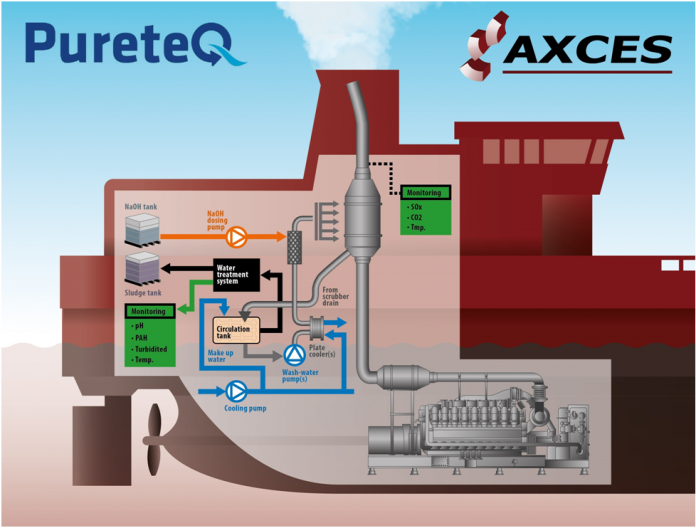

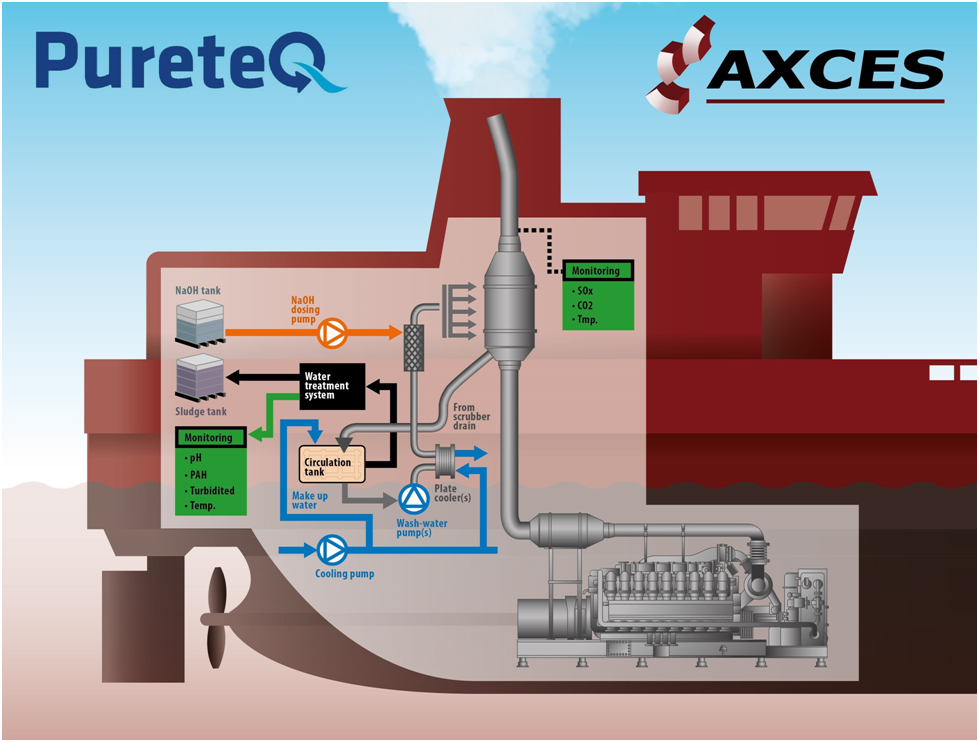

a) Emission monitoring – SO2/CO2 ratio b) Wash water discharge parameters:

i) pH,

ii) Paraffin Aromatic Hydrocarbon (PAH) and

iii) Turbidity

c) UTC (Universal Time Co-ordinated) and

d) Ships position by a Global Navigational Satellite System (GNSS)

2.2. Prompt corrective actions must be taken in case of alarm condition due to short-term increase in maximum allowable SO2/CO2 ratio, or wash water discharge criteria.

2.3. Test discharge water sample for Nitrates at every five yearly class renewal survey. This testing has to be done three months prior to the survey. Additional sample testingmay be required to be done as per requirement of vessel’s flag state. The nitrate discharge data and analysis certificate is to beretained on board the ship as part of the EGC Record Book and can be inspected by PSC or other external parties.

2.4. Test wash water samples during the initial commissioning test and at a twelve monthly interval for a period of up to two years (minimum of three samples). Test samples in accordance with ISO or EPA test procedures for the following parameters.

pH, PAH and oil (detailed GC-MS analysis), Nitrate, Nitrite, Cd, Cu, Ni, Pb, Zn, As, Cr, V.

3.0 DOCUMENTATION AND RECORD KEEPING REQUIREMENTS

3.1. Following documents (approved by Administration/Class on behalf of the Administration) should be available on board at all times. PSCO / Flag inspector / Class surveyors / local authorities may also like to review these documents.

- SOX Emissions Compliance Plan (SECP)

- EGC system

- Technical Manual for Scheme B ( ETM-B)

- Onboard Monitoring Manual (OMM)

- EGC Record book

- CFD Calculation for wash water pH to meet the IMO criteria of 6.5 at 4 meters from the overboard discharge point.

3.2. The maintenance, servicing and adjustments should be recorded in the EGC Record Book. Any EGCS malfunction event should be entered in the EGCS Record Book including the date and time the malfunction began and, if relevant, how it was resolved, the actions taken to resolve it, time when the problem was rectifiedand any necessary follow-up actions.

3.3. Below mentioned alarms require regular testing and records to be maintained in PMS as per maker’s guidelines provided in the manual:

1) SO2/CO2 ratio

2) Wash water discharge PH Value

3) Wash water discharge PAH value

4) Wash water discharge Turbidity

5) Other alarms as mentioned in Maker’s manual

4.0. ADDITIONAL REQUIREMENTS FOR VESSELS USING EGCS IN U.S WATERS:

For the use of EGCS as equivalent method to comply with Reg. 4.1 of MARPOL Annex VI, this information must be submitted by vessel’s flag on IMO GISIS site prior the vessel enters U.S ECA. USCG will check this site to confirm the validity of MARPOL Annex VI equivalency.

a) US-VGP Waters

pH value of water:The Vessel General Permit (VGP)requires vessels operating within 3nm from US baselinehas following additional requirements on pH discharge and on recording, monitoring and reporting as mentioned below:

- pHout at overboard ≥ 6, measured when vessel is stationary (e.g. in port or at anchorage), or

- pHin- pHout ≤2, vessel is moving (e.g. when maneuvering)

- pH CFD calculation is not accepted for pHout determination at overboard

Sampling and Analytical Monitoring requirements (refer VGP section 2.2.26.2.2)

- Must carry out sample analytical monitoring in addition to continuous monitoring of wash water discharge parameters.

- Two samples analysis in the first year of permit coverage or system operation, whichever is later. After the first year, samples must be collected at least once per calendar year.

- Samples are to be taken at 3 sampling location – inlet water, wash water after scrubber (but before treatment) and discharge water

- Annual calibration of all probes/sensors used for continuous monitoring equipment must be carried out.

If vessel intends to use scrubber within 3nm from US baseline then it should be mentioned in EPA’s Electronic Notice of Intent (eNOI).

(b) California Waters :

California Air Resource Board does not allow the operation of scrubber as an equivalent method instead of low sulphur fuel. Scrubbers can be used in ECA zones outside of Regulated California Waters per Code of Federal Regulations, but low sulphur distillate fuel (e.g. MGO or MDO <0.1% S) must be used within Regulated California Waters.

Note 2

a) Various countries, coastal states and ports have implemented local regulations with stringent requirements, restricting or completely prohibiting wash water discharge from open loop scrubbers or prohibiting the use of scrubbers.

b) Recommend to check with port authorities prior using open loop scrubbers in territorial waters of any country.

c) Port authority may carry out stringent checks, when scrubber used in territorial waters of a country. Checks may include data stored – alarms and break downs, EGCS record book for proper entries as per manual guidelines, PMS – maintenance and alarm test records, critical spares maintained on board, training / familiarisation of ship staff, etc.