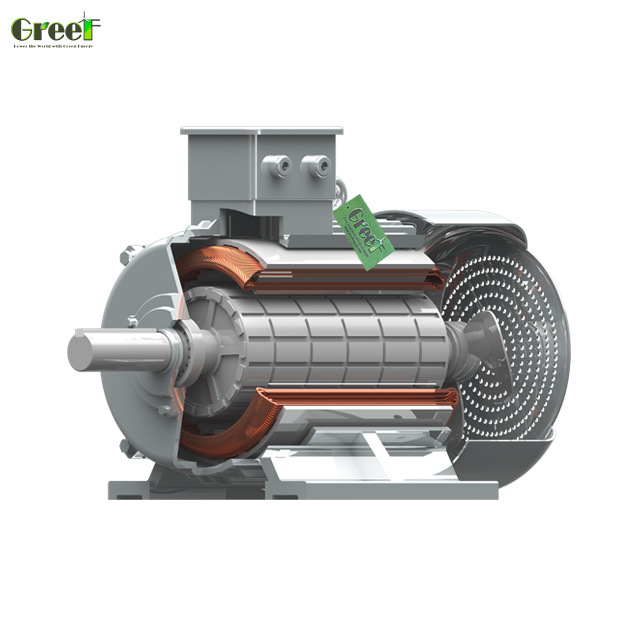

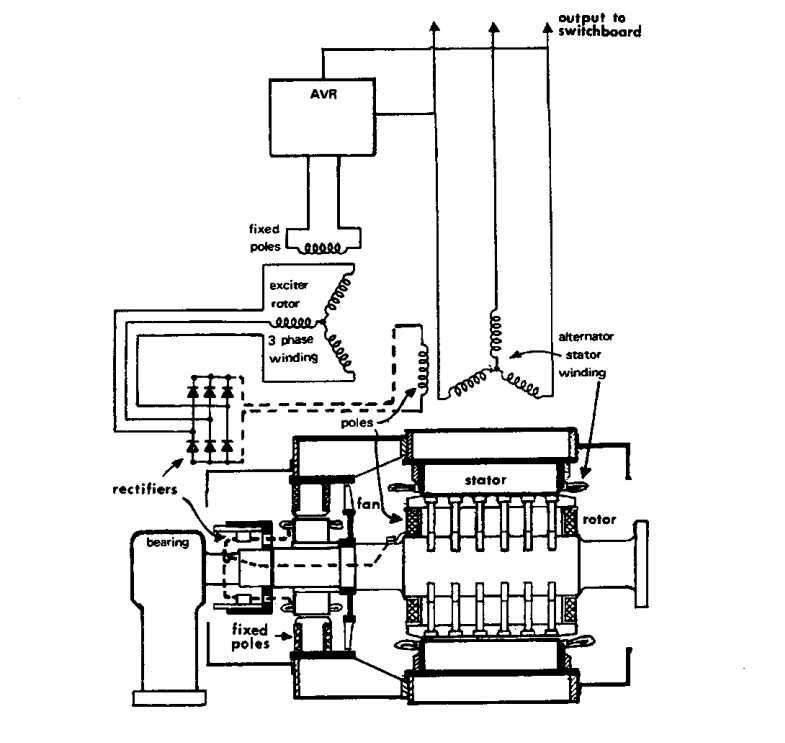

In this machine slip-rings and brushes are eliminated and excitation is provided not by conventional direct current exciter but by a small alternator.

The a.c. exciter has the unusual arrangement of 3phase output windings on the rotor and magnetic poles fixed in the casing. The casing poles coils are supplied with direct current from an automatic voltage regulator(AVR).

Three phase current generated in the windings on the exciter rotor passes through a rectifier assembly on the shaft and then to the main alternator poles. No slip rings are needed.

The silicon rectifiers fitted in a housing at the end of the shaft are accessible for replacement and their rotation assists cooling. The six rectifiers give full wave rectification of the three phase supply.

Output voltage characteristics

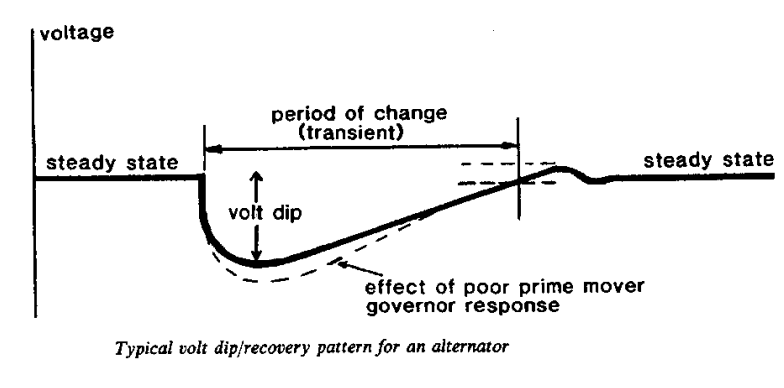

(Transient volt dip alternator response)

A gradual change of alternator load over the range from no load to full load would allow the AVR and excitation system to maintain terminal voltage to within perhaps 2% of the nominal figure.

The pattern of volt dip and recovery when the steady state of a machine running with normal voltage is interrupted by the impact load at the starting of a DOL induction motor.

Typical volt dip recovery pattern for an alternator

The initial sharp dip in voltage followed by a slower fall to maintain voltage is mainly the result of the size and power factor of the load and reactance characteristics of the alternator, Its excitation system and AVR also the prime mover governor.

The brushless alternator have error-operated AVR and excitation system. The voltage has to change for the AVR to register the deviation from normal and to then adjust the excitation for correction.

The suddenness of the initial volt is such that the response from the error-operated system cannot come until the dip is in the second slower stage.

Thus machine can’t prevent the rapid and vertical volt dip due to transient reactance, but the faster acting voltage regulator of the brushless machine will arrest the voltage drop sooner on the slower secondary part of its decent.

Transient voltage dip is usually limited to 15% for a specific sudden load change with recovery to stated voltage within 1.5sec.

Principle of Alternator

Whenever conductor cuts the magnetic field an emf (electromotive force) is induced in it(Faraday’s law). It doesn’t matter whether coil is moving OR the magnetic field is moving. Both configuration works equally well and both are used separately in the combination depending on mechanical, electrical and other objectives.

In case of brushless alternator both configuration are used together in one machine. The exciter has a stationary field coils and a rotating armature. The main alternator make use of the opposite configuration with a rotating field and stationary armature.

A bridge rectifier called the rotating rectifier assembly is fitted on a plate attached to the rotor.

Direction- Fleming’s Right Hand Rule.

Maintenance on Alternator

Safety

- Prime mover is stopped locked off.

- Generator circuit breaker is locked off i.e. Auto start is isolated.

- Electric space heaters are switched off and isolated.

- Put tag ‘MEN AT WORK’.

Safety

- Prime mover is stopped locked off.

- Generator circuit breaker is locked off i.e. Auto start is isolated.

- Electric space heaters are switched off and isolated.

- Put tag ‘MEN AT WORK’.

Checks

- Check/Inspect windings/wiring for sign off damage, loose connection of terminals.

- Check for oil and moisture contamination.

- Remove dirt and dust from winding, use vacuum cleaner, check inlet and exhaust grids are not blocked.

- Clean the stator and rotor terminal winding to remove dust by using dirt free linen cloth or vacuum cleaner.

- Remove oil deposits from windings by washing with degreasing solvents.

- Check insulation resistance (rotor winding to earth, stator core to earth phase to phase, phase to earth). A insulation resistance of minimum 1MÙ is required. If reduced drive out moisture by using heating lamps and injection current.

- Check pedestrial bearing lubrication(oil level).

- Check air gap between rotor and stator(0.3mm).

- Check space heater.

- Check for any loose connection(rotating polyphase rectifier).

- On no-load check the condition of running gears.

- On-load check for stability in parallel operations. Check pedestrial bearing temperature.

- Check the governor excitation system such as AVR, thyristers, diodes, etc. for proper operation and tightness of connection in terminal.

For slip ring Alternator

- Check the rotor slip rings and check that carbon brushes have free movements on their boxes.

- Check the brush pressure by using spring type balance, a pull of about 1-1.4kg is considered appropriate.

- If the brushes have shortened it will result in sparking, replace with correct size and bed them to the curvature of slip rings.

Alternator Safeties

- Over Current instantaneous trip

Setting I~2~10 times rated generated current for 0.2~1 sec

- Under voltage/Over voltage

UV setting – 0.8 * rated generated voltage

OV setting – 1.2 * rated generated voltage

- Over frequency/Under frequency

OF setting – 62Hz (For 60Hz system)

UF setting – 58Hz (For 60Hz system)

- Reverse power relay

This is must for generators intended for parallel operations

Setting 5~15% of rated power (time 0.5~3sec)

- Over Current inverse time relay

Setting 0.7~2 times rated generator current (time 1-1sec)

- Negative Phase Sequence Relay

It measures or determines the amount of unbalance in stator current which is an indirect measure of generator stator and rotor temperature. A relatively small degree of unbalance of stator current produce large temperature variations.

Setting – I~ 0.2 * rated generator current.

- Differential Phases of Current

Difference in current in phases may be due to fault in windings such as short circuit fault.

Setting – 0.1 * rated generator current.

- Earth Leakage Relay or zero phase frequency relay

It is used to measure the earth fault current returning back through the earthed neutral connection.

In HV system, NER is provided

Setting – I~5Amp

Time – 0.1-0.5 sec

- Lock Out

It is a master lock out, hand reset trip Its action is instantaneous when triggered by protective relay. It can trip generator prime mover and initiate generator field suppression along with signal for alarm.

Alternator Plate details

- Maker (Taiyo Electric co. Ltd.)

- Model(FE540S-6)

- RPM/Speed(720RPM)

- Volts(440v)

- Amps (5)

- Frequency(60Hz)

- Power Factor (0.8 Lagging)

- Output (660kw)

- No of Phases (3)

- No of poles (8)

- Insulation class – Armature – F Field – F

- Space heater Output (400w)

- Enclosure (IP22)

- Weight/Mass (1700kg)

- Max. Amb. Temp. (45°C)

- Excitation System – Brushless

- Output (6.8KVA)

- Volts (87.4v)

- Amps (44.8A)

- Power factor (0.95)