An electric propulsion system for a ship is often simply described as a diesel electric or turbo electric system. It is characterised only by the type of prime mover, with no reference to the type of electric propulsion motor, the generator on the electrical power system.

The electrical side of the system will be based on a direct current (d.c.) or an alternating current (a.c.) motor, coupled to the ship’s propeller shaft, with speed and direction of propeller rotation being governed by electrical control of the motor itself or by alternations of the power supply. An electric motor used with a controllable pitch propeller is arranged for constant or variable speed operation.

For direct current (d.c.) propulsion motor, the electrical power may be from one or more d.c. generators or it may be alternator derived and delivered through a rectifier as a d.c. supply. The rectification scheme can in cooperate speed control and the means of reversing.

Power for an alternating current (a.c.) propulsion motor is supplied by an alternating current generator (alternator). The prime mover that provides the generator drive may be a diesel engine, a gas turbine or a boiler and steam turbine installation.

D.C. Propulsion motor

The power for direct current motor is limited to about 8MW so that a.c. machine are used for higher outputs unless rotor is made to the installation of d.c. motors in tandem.

Ward –Leonard Control System (Diesel-Electric)

This system has an a.c. conduction motor driving its direct current generator. Field current for both generator and motor is delivered through a 3phase rectifier from the a.c. supply.

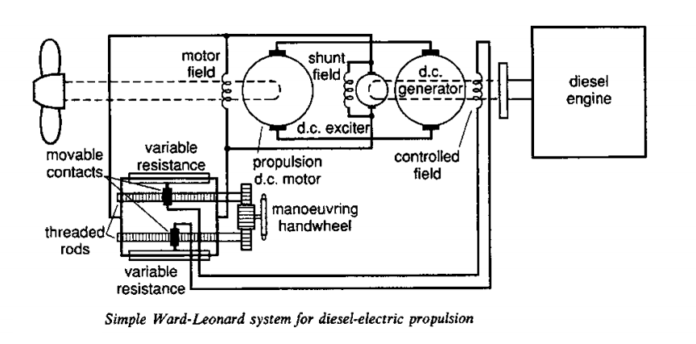

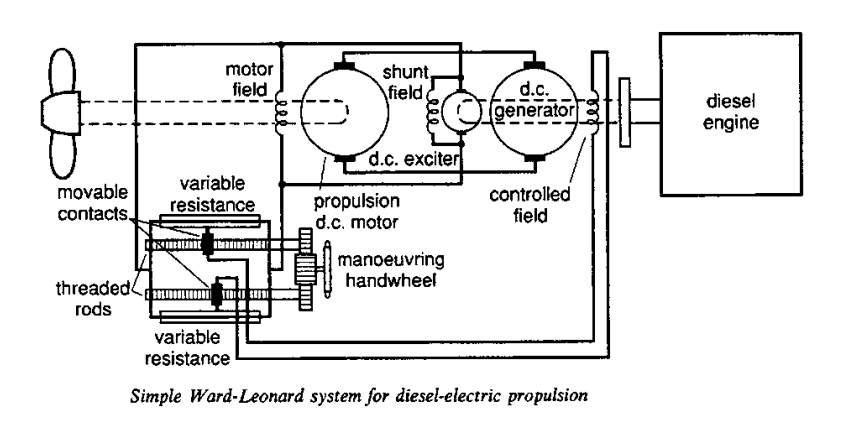

This arrangement is an all d.c. scheme with a diesel engine as the prime mover driving the single d.c. generator at constant speed. An exciter mounted on an extension of the generator shaft provides field current both for the generator and for the direct current propulsion motor. The exciter is itself a d.c. shunt generator.

At Start up, the armature windings of the exciter have current generated in them when they pass through the field emanating from the residual magnetism of the exciter poles. The small current generated initially, circulates through the windings of the exciter poles, strengthening their magnetic fields until full output is reached.

The current generated in the d.c. exciter is delivered unchanged to its own field poles and to the field poles of the d.c. propulsion motor. It is available to the field poles of the generator, but only through the regulating resistances of the maneuvering control.

If the contacts control are at the mid positions of the resistances, then no current flows to the main generator poles and there is no output from it to the propulsion motor.

Rotation of the maneuvering handwheel and gears turns the threaded bars to move the contacts along the resistances, in opposite directions. As the contacts travel towards extremities and resistance lessens, current from the exciter flows to the generator field poles.

The direction of current flow and the level are used to control the output of the generator and, in turn, the propulsion motor. Propeller speed is proportional to the actual voltage produced in the generator and fed to the propulsion motor.

Advantages

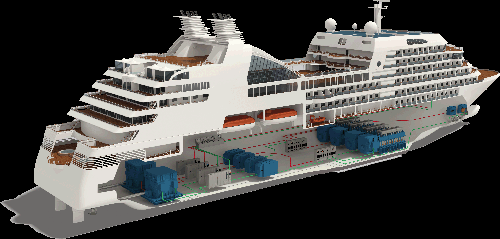

- The large amount of electric power available for main propulsion can be diverted for cargo or dredge pump operation as well as for bow or stern tube thrusters or fire pumps of the emergency and support vessel (ESV).

- Reduction in size of propulsion machinery spaces.

- Electric propulsion separates the shaft and parallel system from the direct effect of a diesel prime mover and from transmitted terminal vibrations.

- Flexible and absence of physical constraints on machinery layout.

- Very smooth speed control system over a very wide range.

- Speed can be controlled in both direction of rotation of motor.

Disadvantages

Higher installation cost and lower efficiency compared with a diesel propulsion system.