Checks on rudder in drydock

- When ship enters dry dock and pumping out water, check water whether water is coming out from rudder or not. If yes, then rudder is breached.

- Open the top and bottom plug and check for any water inside.

- Pressure test the rudder at a water head of 2.46 meters.

- If the rudder is badly rusted or ship is older, surveyor may insist on thickness gauging of the rudder plate.

- Check the condition of the sacrificial anode on the rudder.

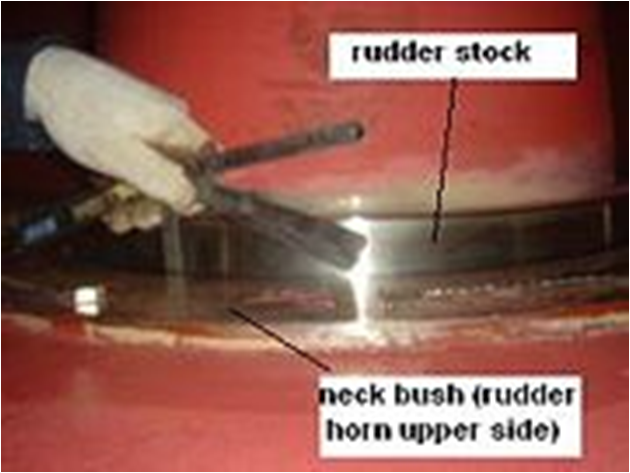

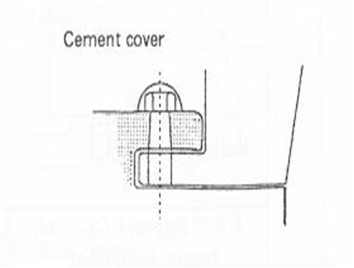

- Check the cement on the coupling bolts for rudder and rudder stock. Remove the cement and check the condition of the palm nut.

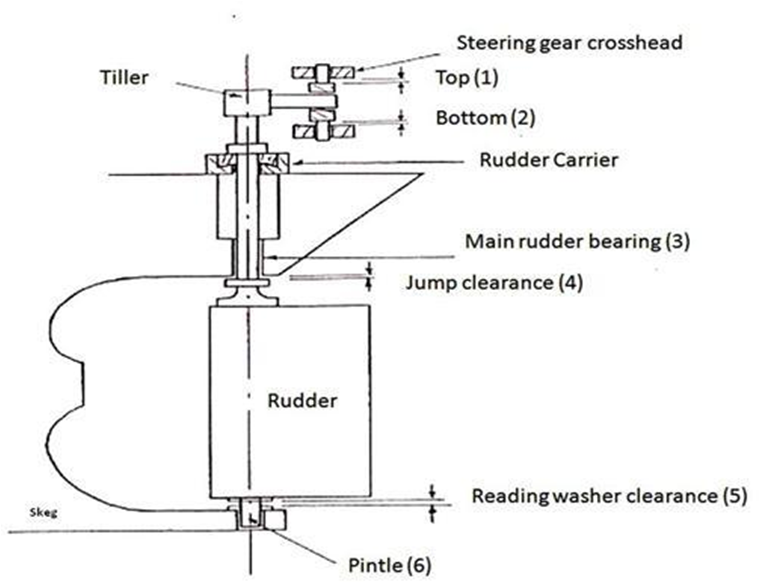

- Check the rudder pintle clearance.

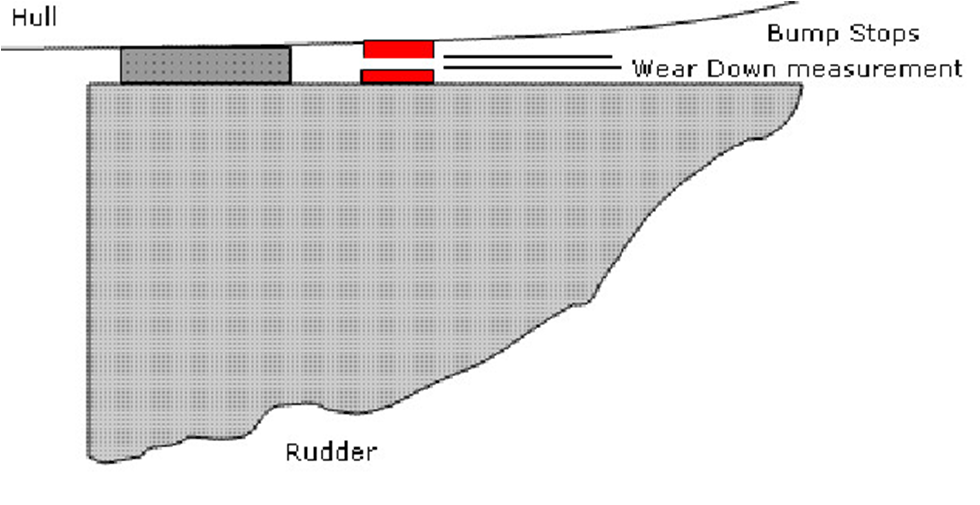

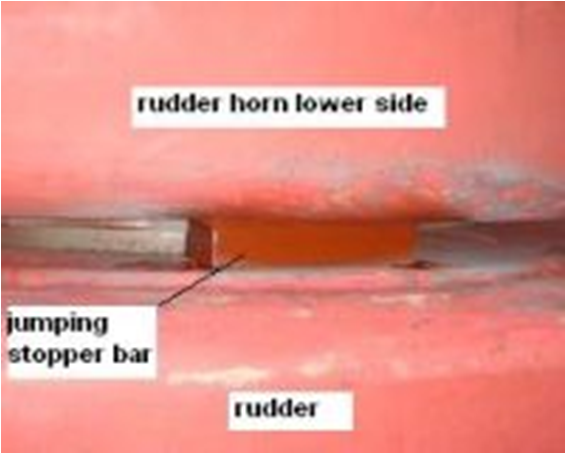

- Check the rudder jumping clearance.

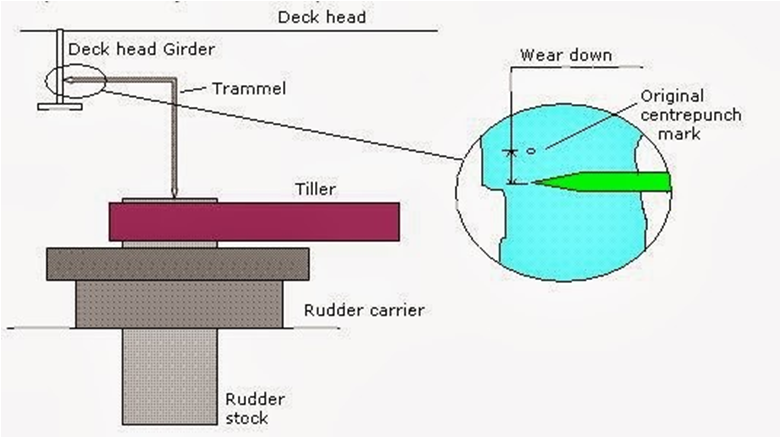

- Check the rudder drop.

- Check the rudder by hammer test by surveyor’s hammer, by tapping on the rudder to evaluate the plate condition.

- Check the actual position of the rudder, compared to rudder angle indicator and see whether any difference is there by bending or deformations

- Carry out a visual inspection.

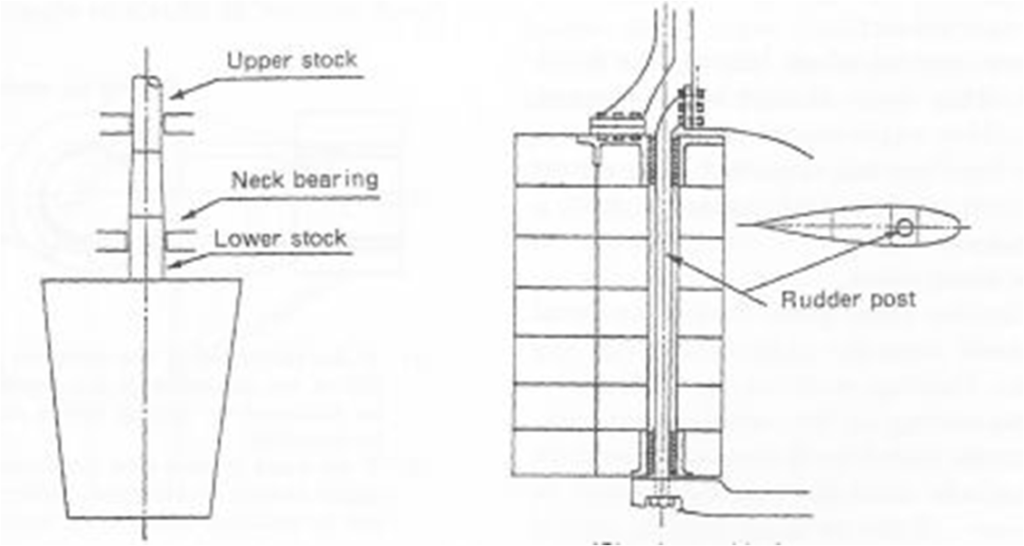

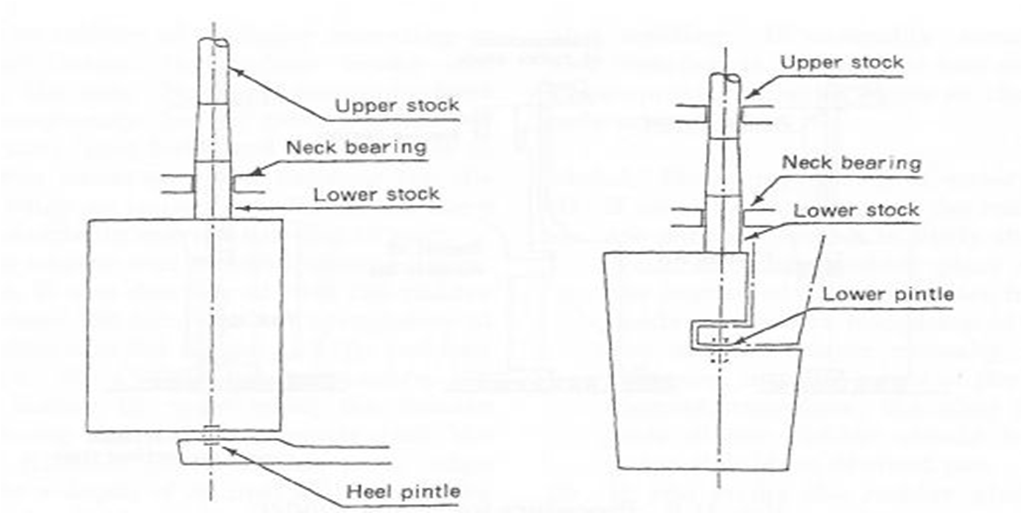

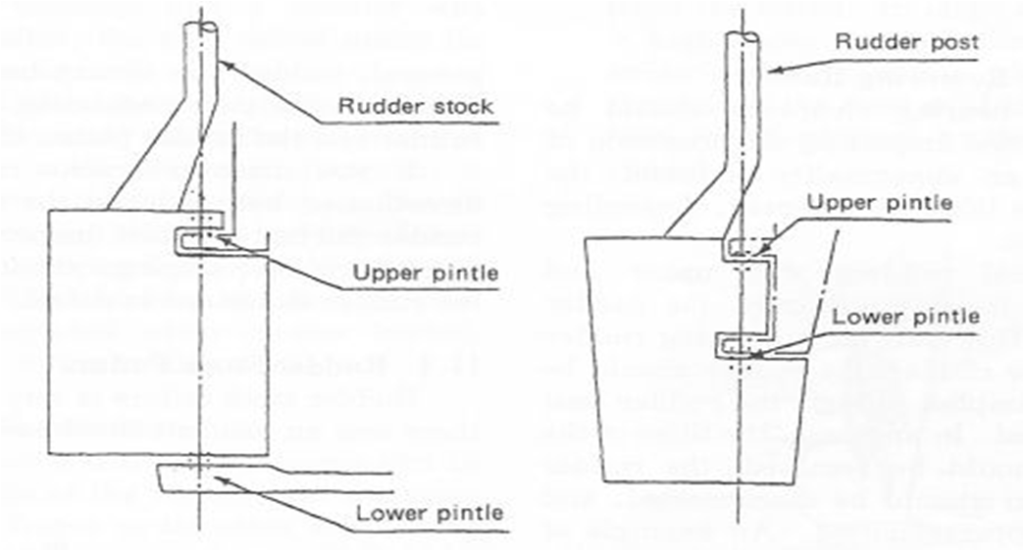

RUDDER WITH SINGLE PINTLE & MARINE RUDDER

RUDDER WITH TWO PINTLES & MARINE RUDDER

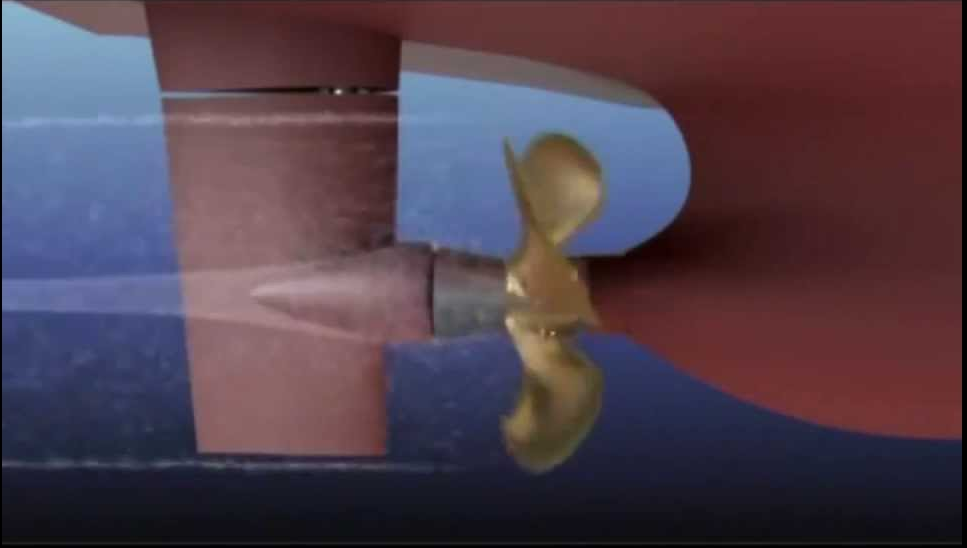

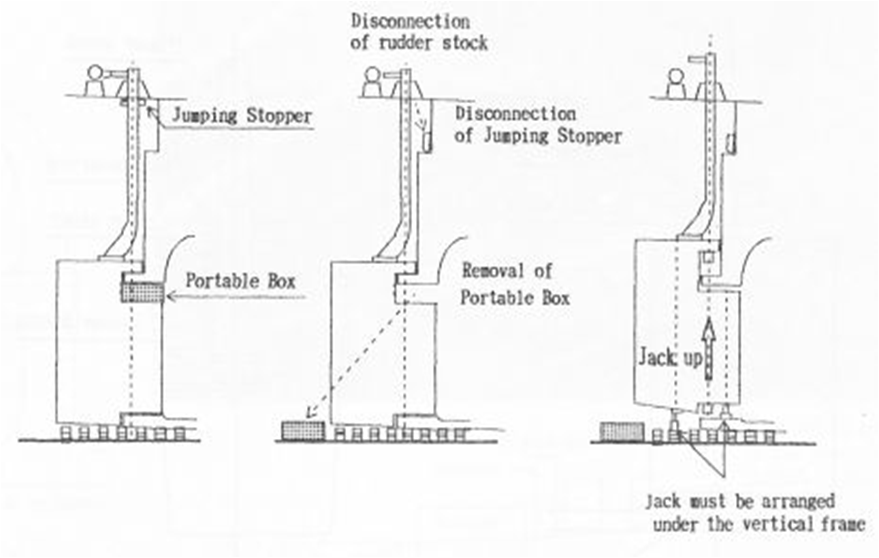

LIFTING UP OF RUDDER

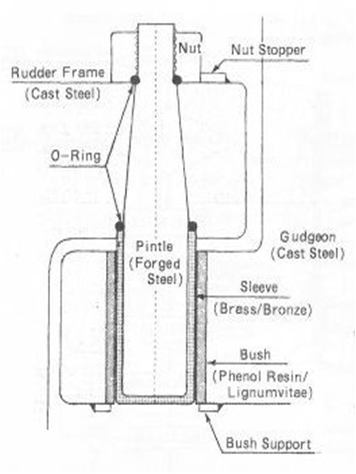

The rudder stock and the pintle are made up of forged steel, the rudder body made by welding steel plates, and pintle bearings are castings.

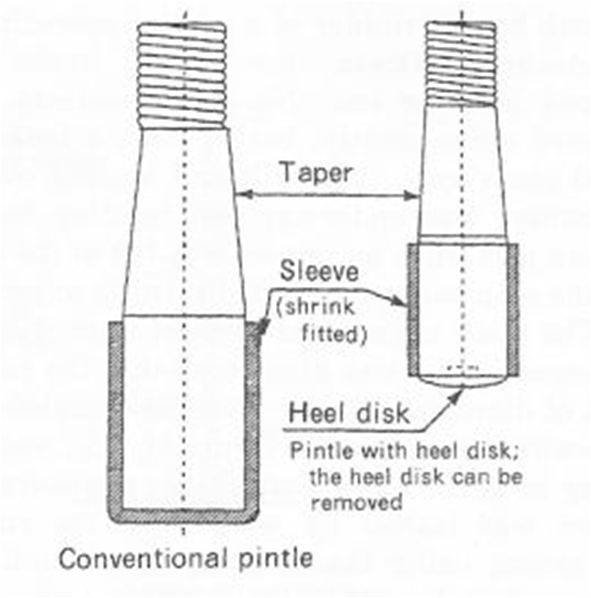

Because the pintle is small, it does not bend. The damages to the pintle are as follows:

(1) Fracture

(2) Sleeve drops off

(3) Corrosion

(4) Wear to sleeve and bush

(5) Sleeve slack

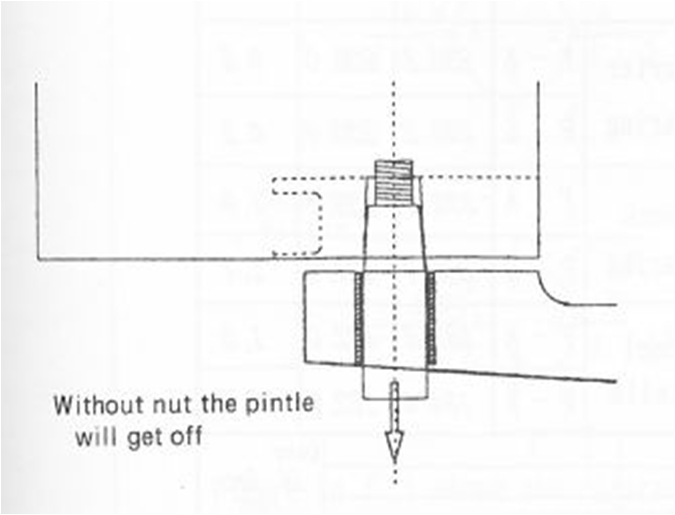

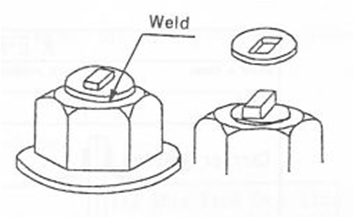

(6) Loss of nut

(7) Wear to nut stopper and bush stopper

In case the nut is corroded or loosened and falls off, there are chances of pintle loss too.

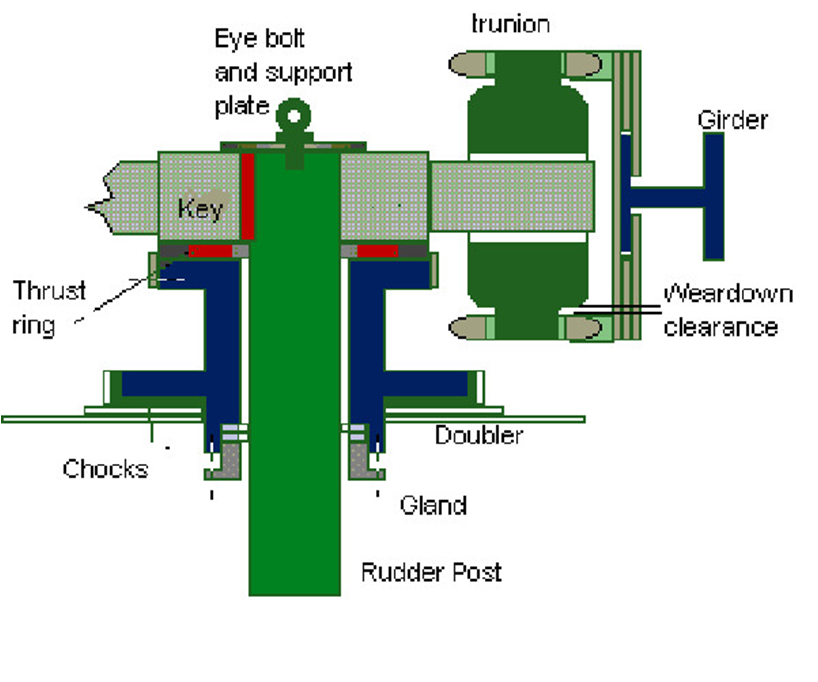

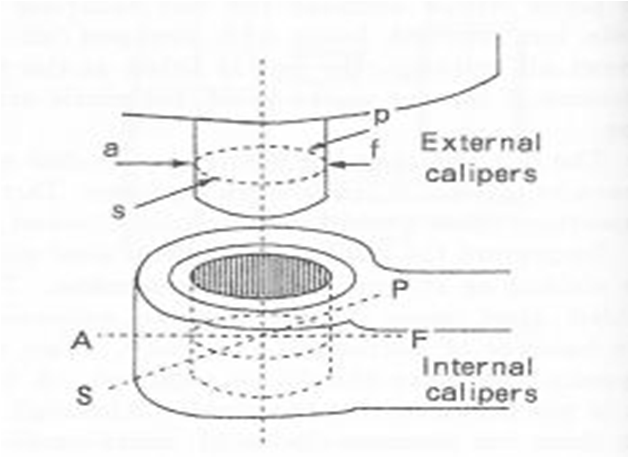

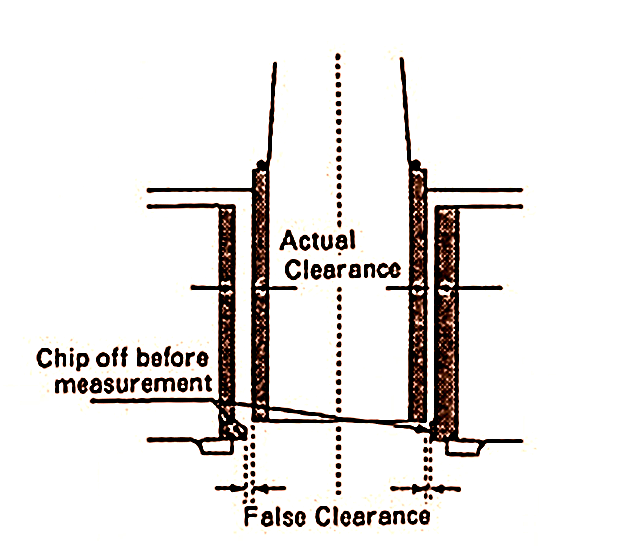

Measurement of all the clearances of all bearings are to be carried out during rudder inspection. So, the clearances of the sleeve and the bush in the longitudinal direction (F~A) and the transverse direction (P~S) of the rudder should be measured.

The outside diameter of pintle (outside diameter of pintle sleeve) using external caliper and the internal diameter of bush using internal caliper have to be measured in the three sections i.e. top, middle and bottom.

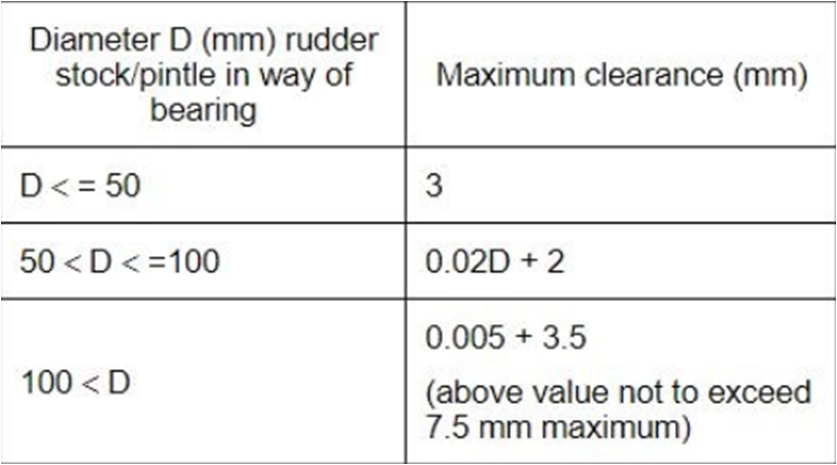

Standard Clearance

Pintle

For a new built ship, the standard clearance is 1.5 mm.

For the ship in service, Maximum allowable clearances between pintle and bush is 6 mm.

IF the actual clearance exceeds above 6mm, the bush should be renewed.

Dimension(1) must be substantially greater than jumping clearance (4) to protect steering gear from damage in the event of grounding of skeg of rudder.

Dimension(2) should be adequate to cater for wear in carrier bearing and substantially greater than riding washer clearance (5).

Usually (1) and (2) are of the order of 20 mm/25 mm on a small/medium size vessel.

If the riding washer clearance has decreased then the carrier bearing is wearing or the skeg is set up. Check for the reduction in steering gear crosshead dimension (2) to verify downward displacement.