The fuel is supplied by the fuel pumps to the fuel injectors or fuel valves. For the fuel to burn completely at the correct time it should be broken up into tiny droplets in a process known as atomisation. These tiny droplets should go far enough into the combustion space so that they mix with the oxygen. The temperature of the droplets rise quickly as they absorb the heat energy from the hot air in the cylinder, and they ignite and burn before they can hit the comparatively cold surface of the liner and piston.

• Fuel injectors attain this by making use of a spring loaded needle valve.

• To provide the correct amount of fuel at the right moment and in a suitable condition for combustion process.

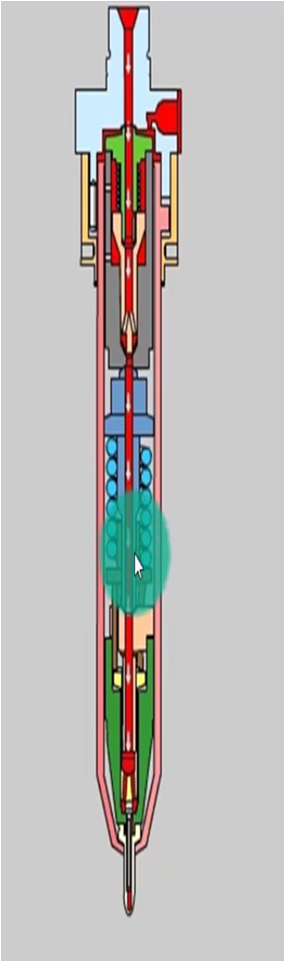

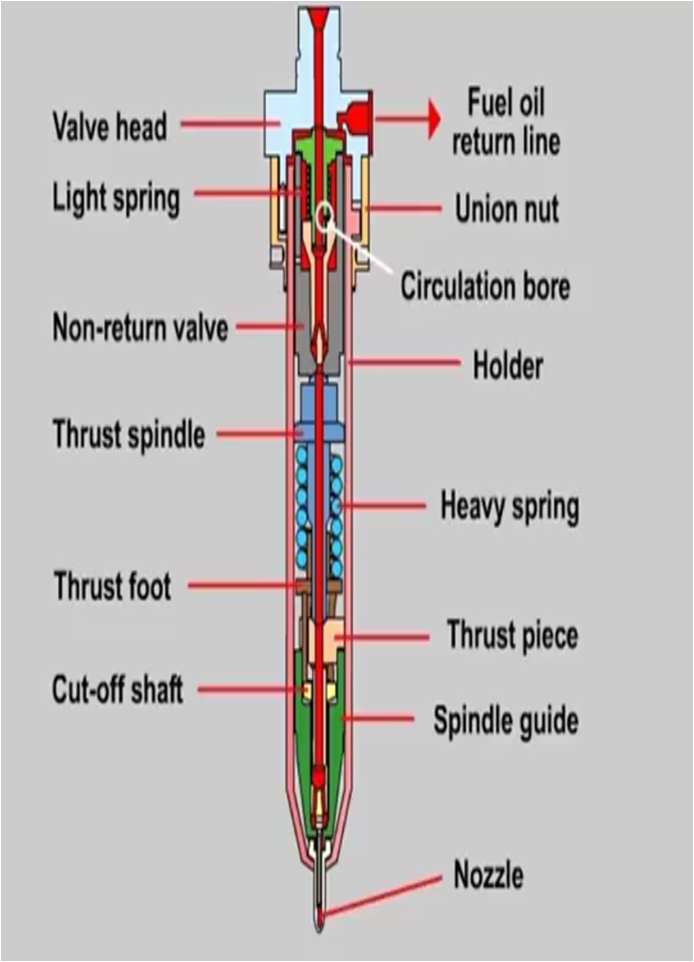

• Basic parts – Nozzle and Nozzle holder or body

• The high pressure fuel enters and travels inside the passage in the body and then into the nozzle surrounding the needle valve

• The nozzle and injector body are manufactured as a matching pair and are accurately ground to give a good oil seal.

• The needle valve will open when the fuel pressure acting on the needle valve tapered face exerts a sufficient force to overcome spring compression

• The fuel then flows inside lower chamber and is forced out through series of tiny holes.

• The number, diameter and angular position of the nozzle orifices are determined by the output of the engine

• The fuel is atomized and injected into combustion chamber

• Once the injector pump cuts off the high pressure fuel supply the needle valve will close quickly under the spring compression force

• The degree of atomization and penetration is dependent on the viscosity of the fuel.

• If the viscosity is very high atomization is reduced and penetration is increased.

• If the viscosity is very low atomization increases and penetration decreases.

• When engine is stopped the fuel booster pump supplies fuel which circulates inside the injector body.

• Older loop scavenged engines may have a single injector fitted centrally in the cylinder head. Because the exhaust v/v is in the centre of the cylinder head on latest uniflow scavenged engines the fuel valves (2 or 3) are arranged around the periphery of the head.

• Some injectors having internal cooling passages in them extending into the nozzle through which cooling water is circulated. This is to prevent overheating and burning of the nozzle tip.

• The pressure at which the injector works can be adjusted by adjusting the loading on the spring. The pressure at which the injectors works vary depending on the engine, but can be as high as 540bar.

• Injectors on latest 2 stroke crosshead engines do not have internal water cooling passages. Injectors are cooled by intensive bore cooling in the cylinder head which is close to the valve pockets and by the fuel which is recirculated through the injector when the cam follower is on the base of the cam.

• Fuel injectors must be kept in good condition to maintain optimal efficiency, and to prevent conditions arising which could lead to damage inside the cylinder. Injectors should be changed with manufacturers recommendations, overhauled and tested. Springs can become weak with repeated operation leading to the injector opening at a lower pressure than designed. The needle valve and seat may wear together with worn nozzle holes will lead to incorrect atomisation and dribbling.