INTRODUCTION

Remote Maintenance Inspections (RMIs) are a new and innovative way to carry out inspections on ships. RMIs involve the use of video conferencing and other technologies to allow surveyors to inspect ships from a remote location, such as their office and other ships.

The Covid 19 Pandemic accelerated the need for remote operations because many marine surveyors were forced to work from home as many government agencies worldwide had enforced travel bans and lockdown measures.

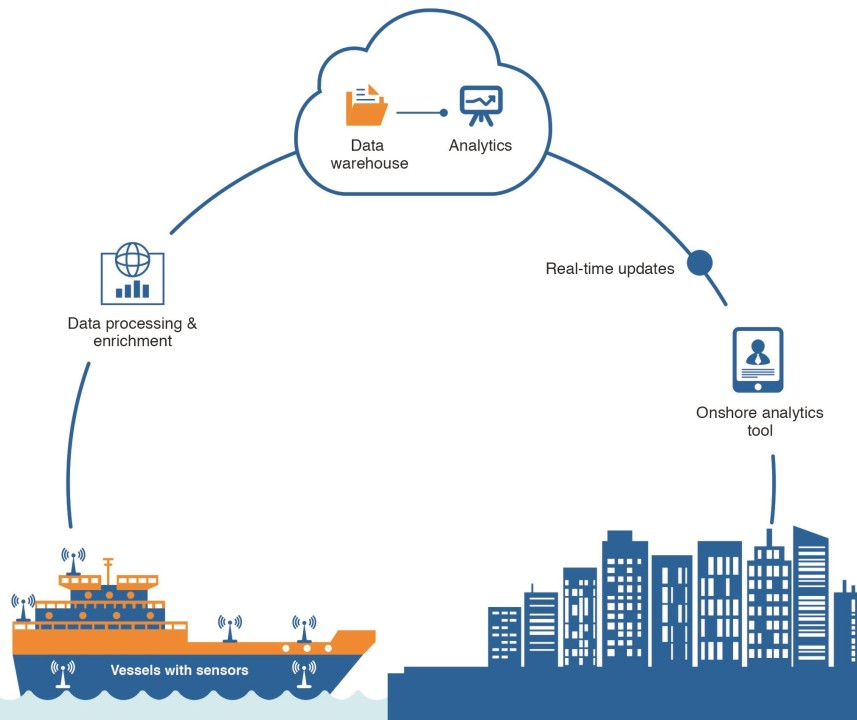

Image credit- DNV Maritime operational

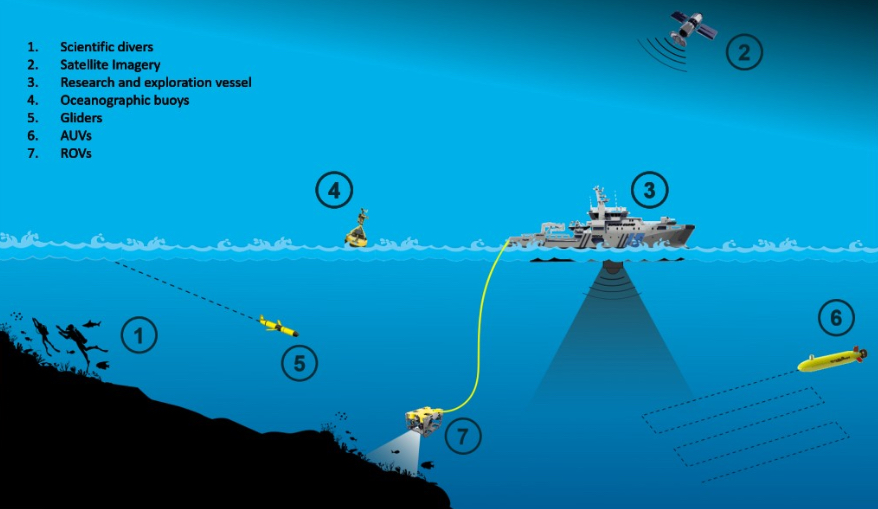

Image credit- Bureau Veritas

(RMIs) BENEFITS OVER TRADITIONAL INSPECTIONS

REDUCED COSTS – RMIs can reduce great amount of money as surveyors don’t need to travel to the ship being inspected. This can save ship owners a significant amount of money.

REDUCED DOWNTIME – RMIs reduce downtime of ships, as they can be carried out as the ship is in port or even at sea.

IMPROVED SAFETY – RMIs also improve safety of inspectors as they do not need to expose themselves to the risks such as falls, trips and hazardous materials.

INCREASED FLEXIBILITY – Remote inspections can be scheduled at times that are convenient for both the ship owner and the inspector, regardless of the ship’s location.

IMPROVED COMPLIANCE – Remote inspections allows experts to review all of the necessary documentation remotely on timely basis.

METHODS USED FOR RMIs

VIDEO CONFERENCING – Video conferencing can be used to allow inspectors to view a ship’s equipment and machinery in real time. Useful for conducting visual inspections and diagnosing problems.

Image credit- Built In

WEARABLE CAMERAS – These cameras can be useful for surveyors to get a first person view of ship’s equipment, to inspect areas difficult to see with a traditional camera such as confined spaces.

DRONES – Drones can be used to inspect areas of ship that are difficult or to reach, such as hull and cargo spaces.

Image credit- Professional Mariner

INTERNET OF THINGS (IoT) SENSORS – Remote sensors can be used to collect data on the condition of a ship’s equipment and machinery and this data can be transmitted to shore-based experts for analysis.

Image credit – LinkedIn

REMOTELY OPERATED VEHICLES – ROVs can be used to conduct underwater inspections of ship’s hulls and propellers.

Image credit- Deepco.com

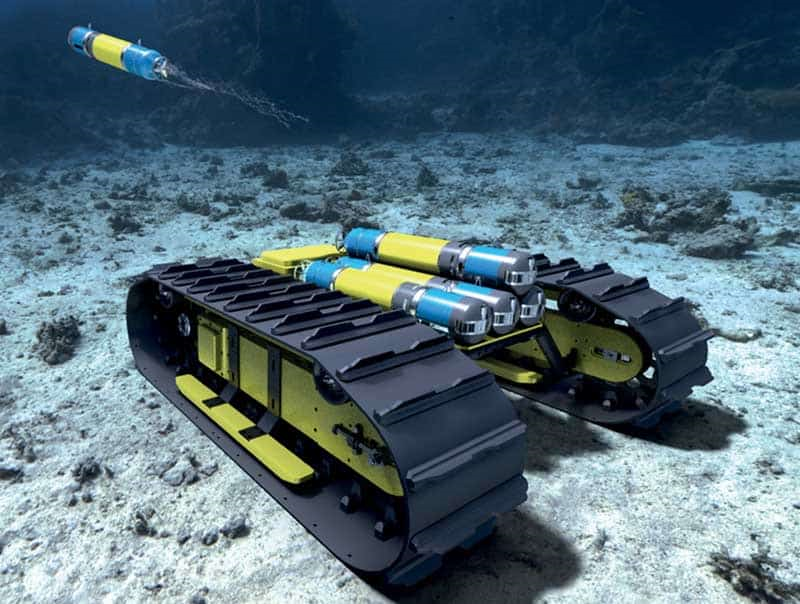

ROBOTIC CRAWLERS – These can be used to inspect areas of ships that are difficult or dangerous to access, such as tanks and holds. This can be useful for identifying damage, corrosion and other defects.

Image credit- Unmanned systems technology

EXAMPLES OF REMOTE MAINTENANCE INSPECTIONS

1) In February 2021, Mitsui O.S.K. Lines, Ltd and its car carrier Orca Ace, gained ClassNK’s Remote Survey (RMSV) notation, which recognizes the vessel’s preparedness for implementing remote surveys.

2) In the beginning of 2021, Bureau Veritas (BV) successfully completed an underwater remote survey using the Seasam technology eco-system from Notilo Plus onboard a Corsica Linea ship.

3) In October 2020, DNV GL and Aker BP jointly conducted a pilot project concerning remote inspections on three of their offshore cranes on the Norwegian Continental Shelf.

4) MOL and Autonomous Control System Laboratory Ltd. Announced in June 2021 the success of a demonstration test using a made-in-Japan flying drone to inspect the hold of an MOL-operated coal carrier.

CHALLENGES OF REMOTE MAINTENANCE INSPECTIONS

Where RMIs offer a number of benefits, there are also some challenges that need to be addressed. One challenge is the need for reliable and high-speed internet connectivity. RMIs rely on video conferencing and other technologies, so its important that the ship being inspected has a good internet connection.

Another challenge is the need for training. Both surveyors and crew members need to be trained on how to use the technologies required for RMIs. This can be challenging, especially for smaller shipowners with limited resources.

CONCLUSION

RMIs offer a number of benefits over traditional inspections, including reduced costs, reduced downtime, and improved safety. However, there are also some challenges that need to be addressed, such as the need for reliable internet connectivity and the need for training. Overall, RMIs offer a number of potential benefits for shipowners, surveyors, and the maritime industry as a whole. As the technology continues to develop and become more widely adopted, it is likely that RMIs will play an increasingly important role in the maritime industry.

However, there are some recent developments which can be looked forward to like,

ARTIFICIAL INTELLIGENCE (AI) – AI can be used to analyse video footage from RMIs to identify potential problems.

BLOCKCHAIN – Blockchain can be used to create a secure and tamper-proof record of RMIs. This can help to improve the transparency and accountability of the inspection process.

AUGMENTED REALITY (AR) – AR can be used to overlay digital information onto the video footage from RMIs. This can help surveyors to better understand the condition of the ship and to identify potential problems.

As these technologies continue to develop, they are likely to make RMIs even more efficient and effective.

Author: Prasad Ravindra Sawant

Reference: Safety4sea