Scrubbers or Exhaust Gas Cleaning Systems as they are normally called the innovative invention which has contributed to the shipping community and to an extent helped in reducing or lessening the pollution caused by particulate matter, Sulphur oxides (SOx), and nitrogen oxides (NOx).

The Scrubbers have become increasingly popular in the maritime industry in recent years as the sulphur emissions from the ships have been limited by the updated international regulations which came into effect from 01 January 2020 under MARPOL. In order to comply with the new regulations vessels are required to use expensive low sulphur fuels or clean the exhaust gas by using scrubbers. However, scrubbers are also expensive to install and maintain, and they have been criticized for their environmental impact.

Image Credit: Daphne Technology SulPure

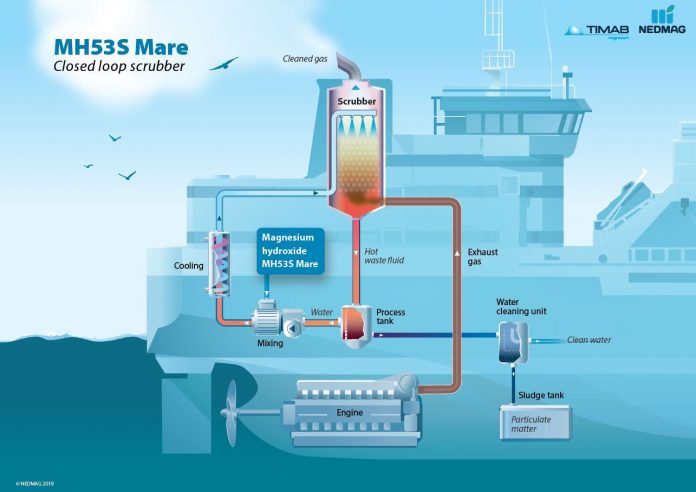

Principal of operation

The operation is such that exhaust gases which are coming out of the engines and boiler are passed through scrubbers at the bottom and made to come in contact with the neutralising medium which can be water or pellets which are alkaline in nature and clean gases are coming out of the funnel to cater IMO norms.

Image Credit: NEDMAG

Further scrubbers can be classified into two categories:

Dry Scrubbers and Wet Scrubbers

Dry Scrubbers

These scrubbers make use of solid lime as scrubbing material which reacts with sulphur dioxide to form calcium sulphite, which on further treatment can be used as a fertiliser or building material which do not pose a threat to the environment.

Wet Scrubbers

These scrubbers make use of scrubbing liquid say sea water or fresh water with additives like soda or limestone which reacts with exhaust gases and cleans it.

Wet Scrubbers are further classified into:

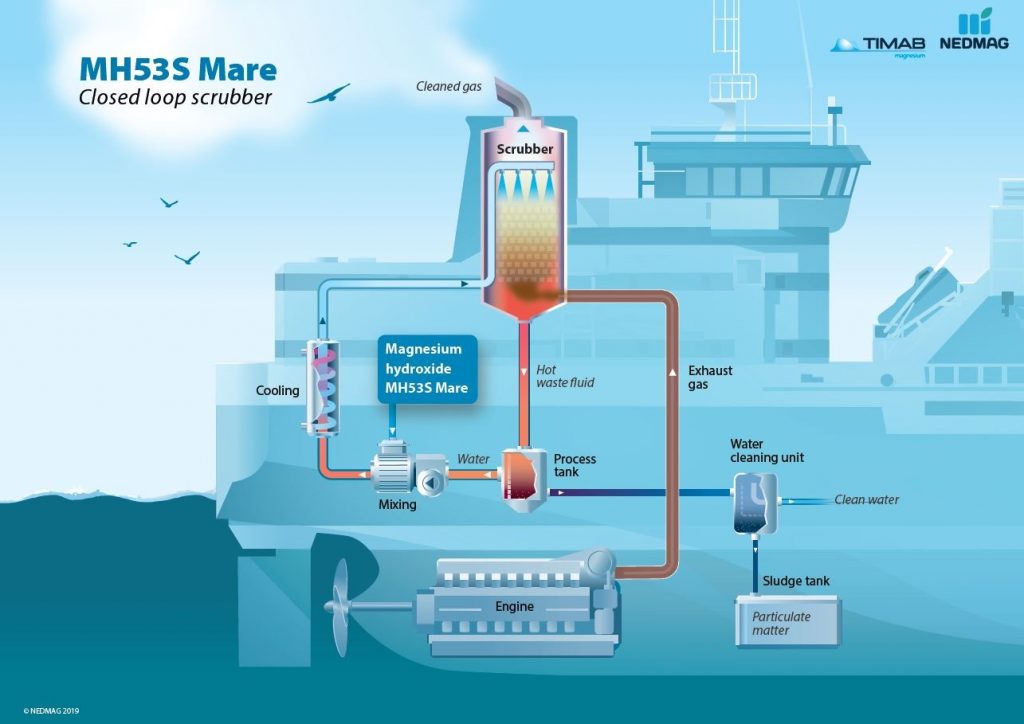

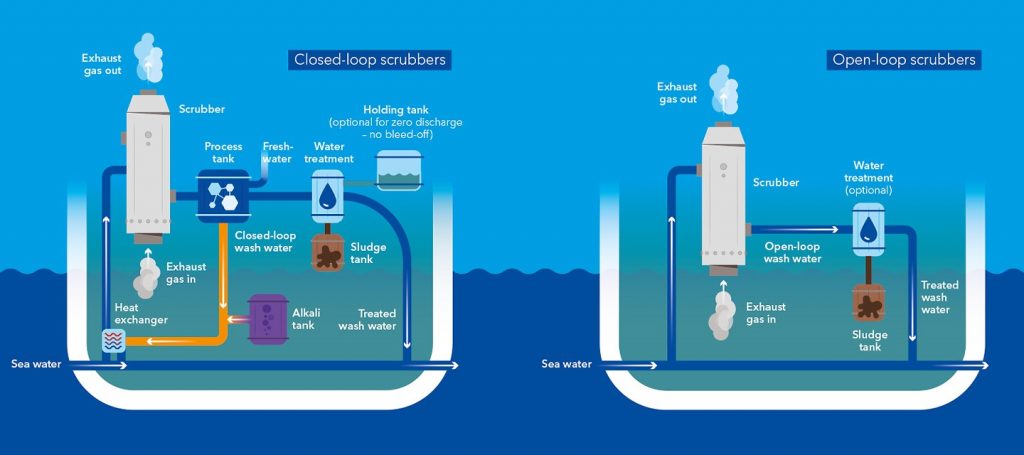

Open Loop & Closed Loop

Open Loop

This concept is such that a system where seawater is made to react with exhaust gases is discharged to sea provided it meets the MARPOL requirements before being discharged.

Closed Loop

This system uses fresh water instead of sea water which contains chemicals like sodium hydroxide and is made to come in contact with exhaust gases. The result of this is that wash water is cleaned in a tank and recirculated again.

Image Credit: DNV GL

IMO Regulations and water discharge criteria

The International Maritime Organisation (IMO) has laid down some regulations in relation to this system.

We know that merchant vessels are limited to using low sulphur fuels which has a maximum sulphur content of 0.5% outside ECAs (Emission Control Area) and 0.1% inside Emission Control Areas (ECAs)like The Baltic Sea Area, The North Sea Area, The United States and The United States Caribbean Sea are mentioned.

As for water discharge criteria are concerned whenever the ECGS system is operated in ports, harbours or estuaries the wash water monitoring and recording should be continuous. Values like pH, PAH, turbidity and temperature should be monitored. Continuous monitoring or recording equipment should be in operation when the ship is en route. Except for short periods of maintenance and cleaning of the equipment.

Residues generated by ECGS should be delivered ashore to shore reception facilities and such residues should not be discharged into sea or incinerated on board.

Ships should record data in the ECGS log and maintain an electronic recording system which should include the date, time and location of storage of disposal.

Image Credit: AIDA Cruises

Benefits and drawbacks of scrubbers

The main benefit of scrubbers is that they allow ships to continue using high-sulphur fuel, as high-sulphur fuel is much cheaper than low-sulphur fuel.

Scrubbers can also help to reduce air pollution and acid rain, which results in a reduction in stroke, asthma, lung cancer, and cardiovascular and pulmonary diseases.

The main drawback of scrubbers is that they are expensive to install and maintain. Another drawback is that open-loop scrubbers discharge seawater back into the sea, along with pollutants that have been removed. This can have a negative impact on marine life and water quality.

Conclusion

Are scrubbers a bane or a boon for the maritime industry?

The answer to this question is complex and depends on a number of factors, including the cost of fuel, the environmental impact of scrubbers, and the specific needs of individual shipping companies. For shipping companies that are operating on a tight budget, scrubbers can be a boon. By allowing them to continue using high-sulphur fuel, scrubbers can save shipping companies a significant amount of money.

However, for shipping companies that are concerned about the environmental impact of scrubbers, they may be seen as a bane.

Author: Prasad Ravindra Sawant, Junior Engineer