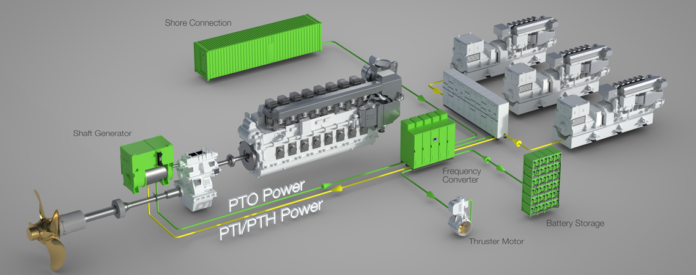

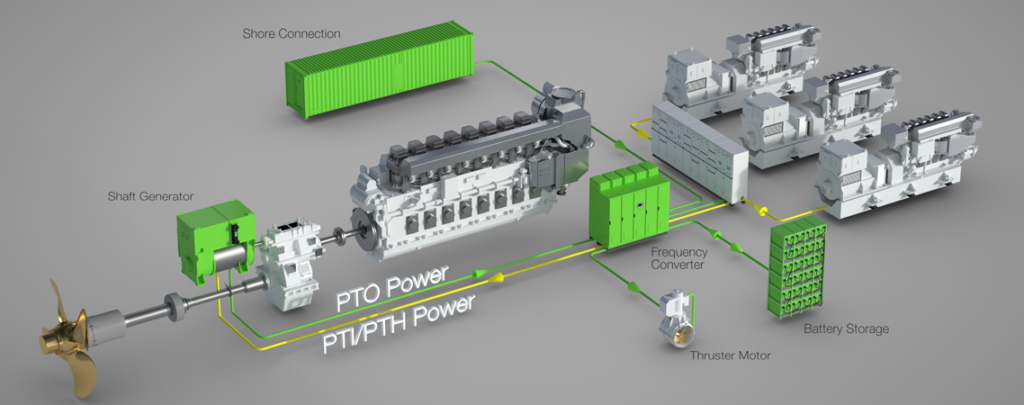

The a.c. shaft generator is a synchronous machine which produces alternating current with a frequency that is dictated by variations in engine speed. At the full rated r.p.m., frequency may match with the electrical system.

The output is supplied to the static converter, which has two main parts:

- Rectifier bridge – To convert/change shaft generator output from AC to DC.

- Inverter – To change DC back to AC, at the correct frequency.

Alternating current from the shaft generator, when delivered to the 3phase rectifier bridge, passes through the diodes in the forward direction only, as a direct current.

The smoothing reactor reduces ripple. The original frequency (within limits) is unimportant once the supply has been altered to d.c. by the rectifier.

The inverter for transposition of the temporary direct current (d.c.) back to alternating current (a.c.) is a bridge made up of 6 thyristors. Direct current available to the thyristors bridge is blocked unless the thyristors are triggered or fired by gate signal. Gate signals are controlled to switch each thyristor on in sequence to pass a pulse of current. The pattern of alternate current flow and break constitutes an approximation to a 3 phase alternating current.

Voltage and frequency of inverter supply to the a.c. system must be kept constant within limits. These characteristics are controlled for a normal alternator by the automatic voltage regulator (AVR) and the governor of prime mover, respectively. They could be controlled for shaft alternator inverter by a separate diesel-driven synchronous alternator running in parallel. Benefits can be obtained from a synchronous compensator which does not require prime mover or driving motor except for starting. The compensator may have its own starter motor or it may be an ordinary alternator with clutch on the drive shaft from the prime mover.

The diesel prime mover for the compensator is started and used to bring it up to speed for connection to the switch board. The excitation is then set to give the reactive power, and finally the clutch is opened, the diesel shut down and the synchronous machine then continues to rotate independently like a synchronous motor, at a speed corresponding to the frequency of the a.c. system.

A synchronous compensator is used with the monitoring and controlling system, to dictate or define the frequency. It also maintains constant a.c. system voltage, damps any harmonics and meets the reactive power requirements of the system and convertor, as well as supplying in the event of a short circuit the current necessary to operate trips.

The cooling arrangements for static frequency convertors include the provision of fans as well as the necessary heat sinks for thyristors.

Due to the many advantages of shaft generator systems, more and more vessels are equipped with them. In summary, some of the greatest benefits include the following:

- Lowering of fuel and lubrication costs

- Reduction of maintenance costs and personnel on board

- Return on investment in 2 to 4 years

- Increased safety for ship and crew

- Low noise power generation

- Smaller or fewer diesel generator sets

- Continuous parallel operation together or combined with diesel generator sets