- The variable delivery pump can run continuously in one direction, but have the cabpability of infinitely changeable discharge i.e., from zero to maximum in either direction.

- This is attained by changing the stroke of the pump piston. For small ruder movements, piston stroke is small and for full rudder movement the stroke becomes full.

- Normally variable delivery pumps are classified as

- Axial piston ( swash plate pump)

- Radial piston pump (hele-shawpump)

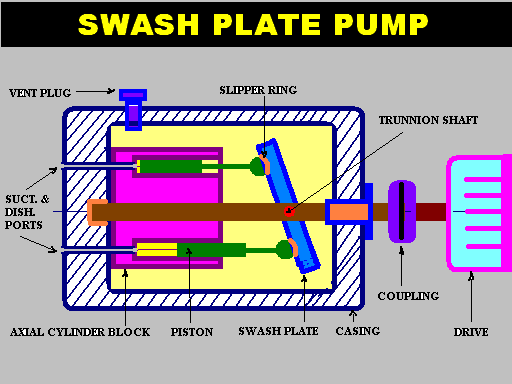

SWASH PLATE PUMP

- Construction :

- This has a circular cylinder block with axial cylinders on it’s pitch circle around the input shaft with which it revolves.

- The individual port holes terminate in a drilled port holes at the end face of the block with valve plate.

- The port holes are connected by external pipes to the steering cylinders.

OPERATION OF PUMP

- The driving shaft rotates the cylinder barrel and piston.

- The external trunnion shaft enables the swash plate to be moved about it’s axis.

- When the swash plate is in vertical position, no pumping takes place.

- When swash plate is tilted to one direction one side port becomes suction and the other port on other side of the centreline, become discharge because of the pumping action.

- For opposite direction of tilt, the direction of flow is reversed.

- Stroke length of the piston and hence the quantity of flow of fluid depend on the angle of tilt of the swash plate.

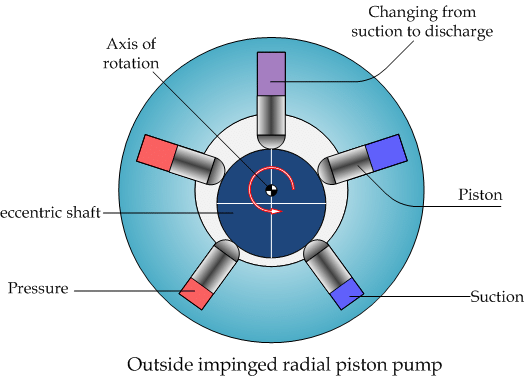

HELE SHAW PUMP

- CONSTRUCTION :

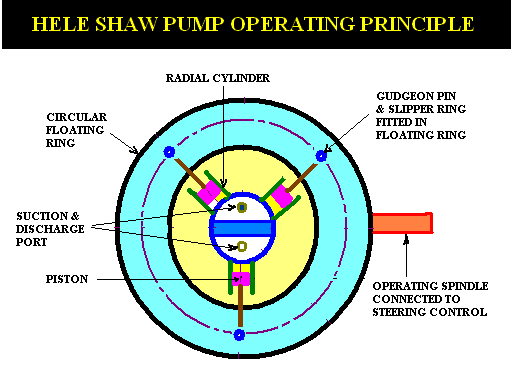

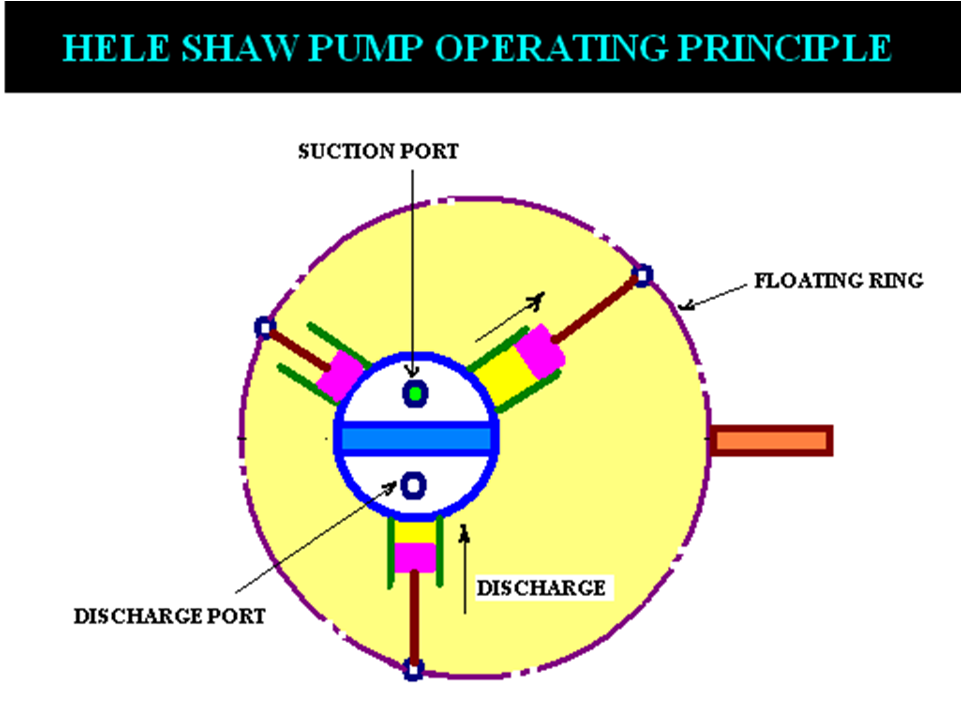

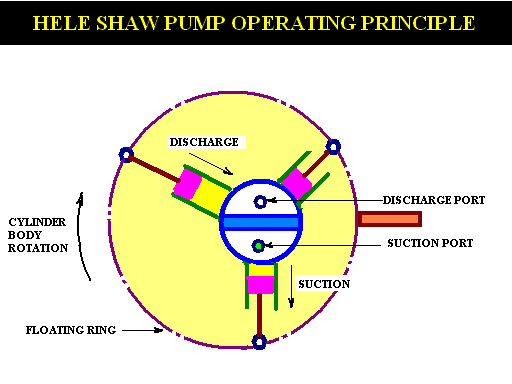

- The circular cylinder body driven by constant speed electric motor rotates around a central valve (tube) arrangement.

- The cylider body is supported by ball bearings which are installed on inner side of the body casing.

- The cylinder body is connected to the central valve arrangement by ports, which are further connected to the outer casing and finally to the ram cylinders for supply & delivery of oil

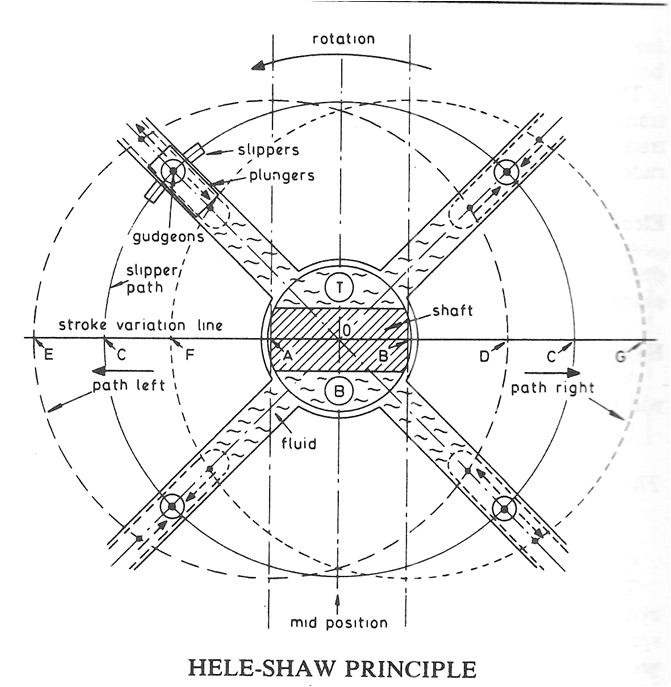

- A number of piston fit in to the radial cylinders & these pistons are fastened to slipper rings by gudgeon pins.

- The slipper rings fit in to the circular track (grove) in floating ring.

- The floating ring is supported by ball bearings on either side, which are further installed on a guide block.

- The guide block attached with the control rod can be moved horizontally at right angle to the pump shaft axis.

- Two spindles which pass out of the pump casing is attached to the guide block, control the movement of the floating ring.

- Pump is usually provided with odd number of cylinders, usually seven or nine to produce even hydraulic flow and better pump balance.