- Condition essential for clean , crisp and complete combustion

- Adequate air at temp above self ignition temp of fuel

- Air of correct density

- Control penetration

- Correct injector tip with orifice match above condition so providing correctly atomized fuel

- An additional factor to be considered is ignition delay , the ID is the time period between injection into combustion chamber and start of ignition of the fuel

A quality has detoriated over the years, ID has become longer

- An allowance has to be made for the longer ID to prevent combustion of fuel taking place so late in cycle.

- The air temp at the end of compression depends upon the speed of compression but as piston approaches TDC it slows down.

- The area of metal surrounding the combustion chamber is large compared to enclosed volume . The air temp is at higher temp than the combustion chamber walls so because of slower compression and low surface temp the air temp starts to reduce as the crank covers those few degrees of TDC

- At low RPM the air tempreture is lower at end of compression . Some form of compensation is essential to ensure that the fuel is injected as far as possible in the air when a temperature of air is highest.

- The technique of injecting fuel by adjusting the start of fuel injection timing whilst engine is running is employed is known as VIT

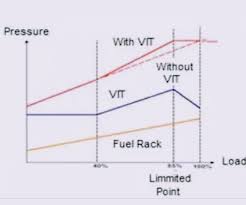

- The VIT Term indicate a mechanism that advances the timing automatically , VIT index increase from 40-80per of MCR and then retards from 80- 100 per of MCR

- This results in improved ignition qualities of part load condition thus achieves fuel economy.