Ammonia has a potential role as a marine fuel. With an upcoming need for fuels that leave no carbon footprint, ammonia is a promising resource. The adoption of the Initial International Maritime Organization Strategy on Reduction of Greenhouse Gas Emissions from Ships by IMO Marine Environment Protection Committee (MEPC) Resolution MEPC.304(72) in April 2018 shows IMO’s dedication to the Paris Agreement. The IMO strategy includes initial targets to reduce the average carbon dioxide (CO2) emissions per transport work from 2008 levels by at least 40% by 2030 and 70% by 2050. For better energy efficiency, IMO requires the CII rating (Carbon Intensity Indicator) to be recorded in a Statement Of Compliance that is elaborated in the ship’s SEEMP (Ship Energy Efficiency Management Plan).

Credit: Badal M @lifewithbadal

Each ship must calculate its EEXI (Energy Efficiency for Existing Ship Index) to the EEDI (Energy Efficiency Design Index). These targets also seek to reduce the total annual GHG emissions from shipping by at least 50% by 2050. Technical and operational approaches as well as the use of alternative fuels will also help to achieve these goals. Ammonia (NH3) is a zero-carbon fuel that may enhance the global market relatively quickly and help meet the GHG reduction target for 2050 set by the IMO. Ammonia offers ship owners and operators a zero-carbon tank-to-wake emissions profile, regardless of the source of the fuel meeting SDG (Sustainable Development Goals). The below-listed characteristics are what make ammonia competent and efficient as a marine fuel.

- Low Fire Risk

Ammonia is a flammable gas with a narrow flammability range. Its flammable range in dry air is between 15.15% and 27.35%. It has an auto ignition temperature of 651 °C. The risk of an ammonia fire is less compared to other fuels because of its narrow flammability range, relatively high ignition energy (2-3 orders of magnitude higher than common hydrocarbons) and low laminar burning rate (more than four times less than methane [< 0.010 m/s]).

- Renewable Production

It can be produced from fossil fuels such as natural gas as feedstock, or with renewables. The reason why ammonia is considered over hydrogen as a fuel is that when used as a fuel, hydrogen is also zero carbon however, if hydrogen is produced from a non-renewable feedstock, such as non-renewable natural gas through a process using energy not from renewable source, the process could produce significant emissions, which may be hazardous for the environment.

- Storage

Ammonia maintains a liquid state at -33.6 °C and 1 bar or 8.6 bar and 20 °C. Industrial scale storage uses low temperatures, which requires energy to maintain. This option may have a lower capital cost than pressurization in some cases, due to the lower storage design pressures. However, pressurized storage in Type C tanks (approximately 18 bar) may be a convenient marine solution and would eliminate the need for additional re-liquefaction equipment to be installed onboard.

- Bunkering

Ammonia can be stored in liquid form by pressurized, semi-refrigerated or fully refrigerated methods depending on the needed volume for safe storage, varying from small pressurized 1,000-gallon nurse tanks up to liquefied 30,000-ton storage tanks at distribution terminals. During the transfer from one tank to another, either “cold inbound” or “warm inbound” is chosen as a result of the transferred volume and re-refrigeration process. The capacity of an onshore full-pressure non-refrigerated tank is usually limited. The overall handling can be energy-intensive. Three modes of future ammonia bunkering via truck, tank or ship are envisaged.

Solid Oxide Fuel Cells (SOFC)

source: Wood Mackenzie

WHY AMMONIA WHEN HYDROGEN CAN BE OPTED?

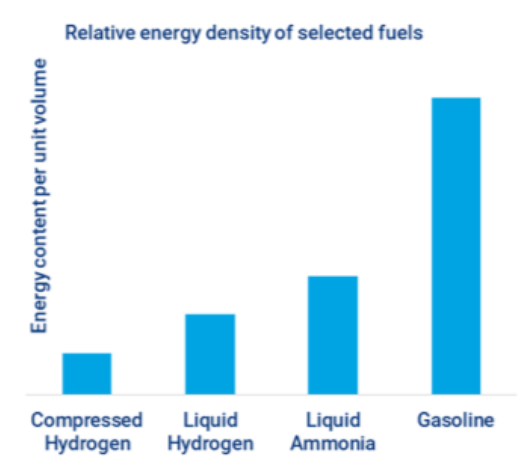

Hydrogen offers a high energy content per mass, high diffusivity, and high flame speed. Hydrogen as a fuel has been demonstrated in internal combustion (IC) engines, gas turbines, and fuel cells. However, it requires cryogenic storage (-253 °C or lower) and dedicated fuel supply systems for containment. Significant technical advances are needed before hydrogen can be considered a viable, large-scale, commercial fuel option, particularly for marine applications where energy content on a volumetric basis is low for hydrogen (9.93 GJ/m3) and application would therefore significantly impact ship design. Energy loss during storage and boil-off gas generation are also challenges for application. Compared to hydrogen, ammonia storage is more practical due to its energy density and liquefaction temperature (see Figure).

To use NH3 in fuel cells (A fuel cell is an electrochemical cell that converts the chemical energy of a fuel and an oxidizing agent into electricity through a pair of redox reactions), the hydrogen contained in the molecule must be separated out. Although it is possible to achieve this through an external reformer so that the hydrogen can be used in low-temperature fuel cells such as a polymer electrolyte membrane (PEM), using ammonia directly in high-temperature fuel cells such as a solid oxide fuel cell (SOFC) can be a more efficient solution. There are also other advantages of using ammonia in SOFC, such as high electrical efficiency, the absence of NOx production and the lack of vibration. Fuel cell development is not as mature as IC engines and typically has a higher cost. These factors are expected to show gradual improvement as research continues. An additional

shortcoming of SOFC compared to PEM is the sensitivity of the solid oxide ceramic materials used to heat gradients, which requires relatively long and careful start-up and shut-down procedures and often lasts for hours. Ideally, SOFC plants should be run continuously to minimize the risk of permanent damage. This would typically require the use of batteries for energy storage to accommodate fluctuations in load demand.

AN ONGOING RESEARCH

As an ongoing research Viking Energy 5, an offshore vessel, was retrofitted with a 2MW ammonia fuel cell, allowing it to sail completely on clean fuel for up to 3,000 hours annually. It is a proof-of-the-concept project for long-range zero-emission large ship voyages. The ammonia fuel cell system will be installed in late 2023. Yara International is contracted to supply green ammonia produced by electrolysis. This will be delivered to Viking Energy in containers for easy and safe refuelling. The project also tests the viability of sustainability sourced ammonia in a solid oxide fuel cell system for a commercial ship

Author: Khushi

References

- American Bureau of Shipping (ABS) publication2- Setting the Course to Low Carbon Shipping: Pathways to Sustainable Future https://sustainableworldports.org/wp-content/uploads/ABS_2020_Pathways-to-sustainable-shipping-report.pdf

- Press release article5, January 23, 2020, Fuel Cells and Hydrogen Joint Undertaking, Major project to convert offshore vessel to run on ammonia-powered fuel cell, can be found online at https://www.fch.europa.eu/press-releases/ major-project-convert-offshore-vessel-run-ammonia-poweredfuel-cell

- Press release article 3, January 11,2022 “What role will Ammonia play in global hydrogen trade”, can be found online at https://www.hellenicshippingnews.com/what-role-will-ammonia-play-in-global-hydrogentrade

- Press Release Article1 , July 14,2021 by Panos Koutsourakis. The Maritime Executive, powering a low carbon fuel can be found online at https://maritime-executive.com/editorials/powering-a-low-carbonfuture-with-methanol-as-a-marine-fuel

- https://issuu.com/justin777/docs/csi_winter_2020_mag_hr

- https://safety4sea.com/wp-content/uploads/2021/01/Ammonia_as_Marine_Fuel_Whitepaper_20188.pdf

- https://www.bunkerspot.com/features-environment/item/putting-ammonia-to-the-test

- https://blog.opisnet.com/zero-carbon-fuels-set-to-transform-the-future-of-shipping