Principles for connecting the dehumidifier and recommended system

The dehumidifiers must be connected to the engine by means of flexible hoses. It is recommended to use steel wire reinforced plastic hoses. Same type as normally used for ventilation systems. The hoses should not be longer than necessary, & sharp bends should be avoided.

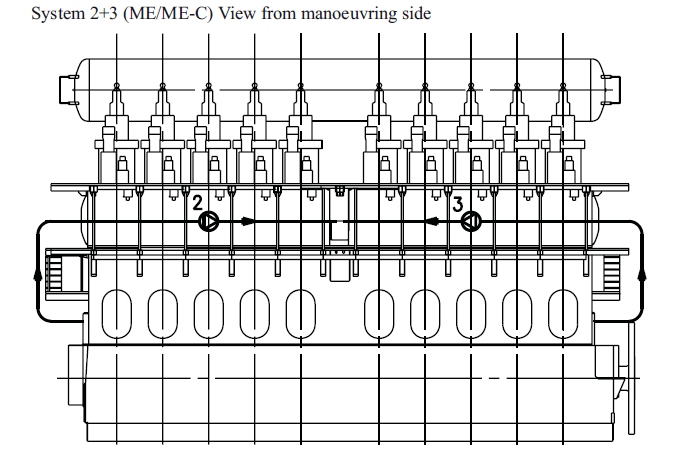

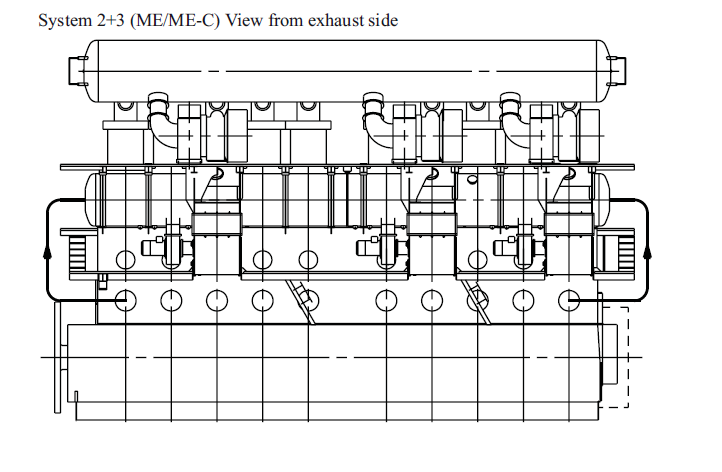

It is recommended to use one dehumidifier for circulating the dry air through the scavenge air chamber and exhaust gas receiver(system 1) and one dehumidifier for circulating dry air through the camshaft housing, chain case and crankcase(system 2). If the chain case is placed in the centre of the engine, it is necessary to use two dehumidifiers to circulate the dry air through the camshaft housing, chain case and crankcase(system 2 + system 3).

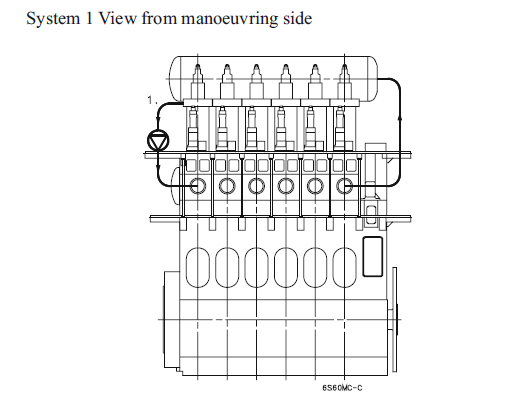

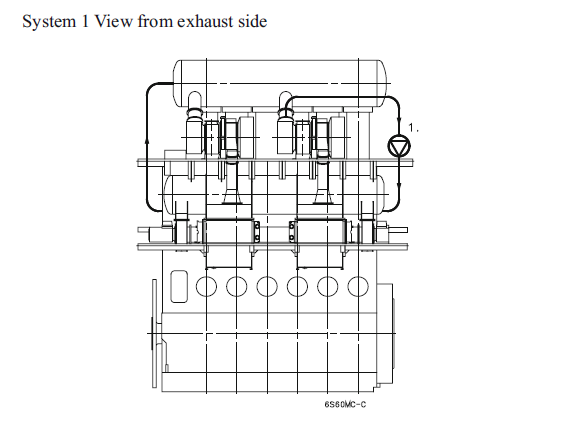

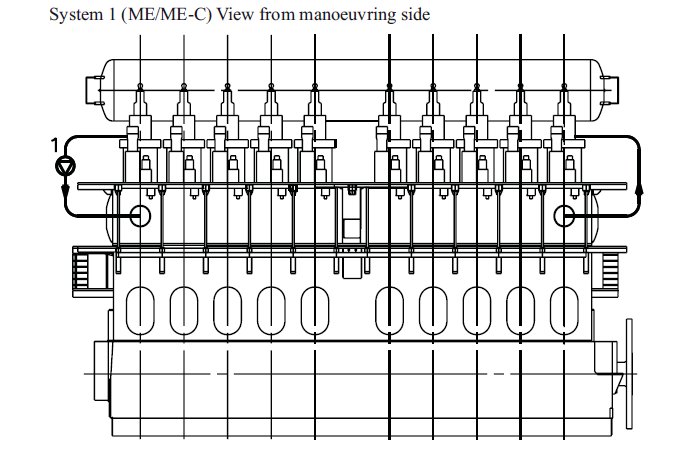

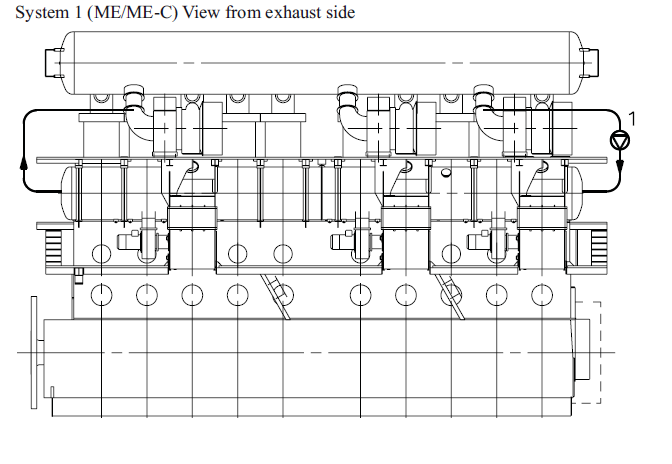

System 1:

Connect the dry air outlet(process air) from the dehumidifier to the dummy cover placed at the fore-most cleaning cover on the cylinder frame with a flexible hose.

Connect the flexible hose from the aft-most cleaning cover on the cylinder frame to the dummy cover on the aft-end man hole cover of the exhaust gas receiver, or if more than 1 turbocharger, to the aft-most compensator for the turbocharger of the exhaust gas receiver.

Connect the flexible hose from the fore-most compensator for the turbocharger of the exhaust gas receiver to process air inlet of the dehumidifier.

The dehumidifier can be placed at the top gallery, fore-end.

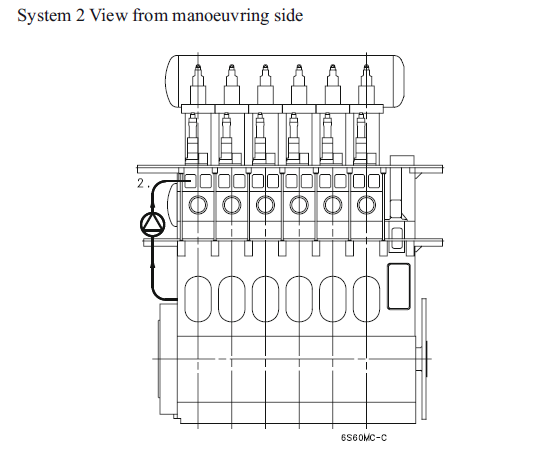

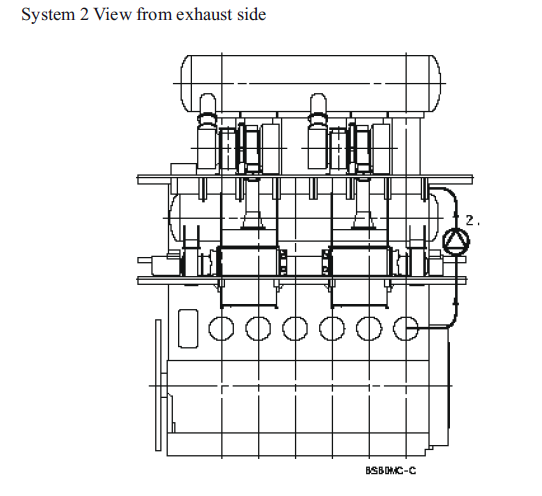

System 2:

Connect the dry air outlet (process air) from the dehumidifier to a dummy cover placed at the fore-most cover on the camshaft housing with a flexible hose. For the ME/ME-C connect to a dummy cover on the chain case.

Connect the flexible hose from a dummy cover at the fore-most relief valve to the process air inlet of the dehumidifier.

The dehumidifiers should be placed at the lower gallery at the manoeuvring side, fore-end.

System 3: (in combination with system 2)

Connect the dry air outlet (process air) from a second dehumidifier of the same size as in system 2 to a dummy cover placed at the aft-most cover on the camshaft housing with a flexible hose. For the ME/ME-C, connect to a dummy cover on the chain case.

Connect a flexible hose from a dummy cover at the aft-most relief valve to the process air inlet of the dehumidifier.

The dehumidifiers should be placed at the lower gallery at the manoeuvring side, aft-end.

Note:- Keep the hoses of both system 2 & system 3 the same length.

The regenerating air inlet is taking the regenerating air from engine room.

The regenerating air outlet (wet air) is either led out into the engine room (engine room must be well ventilated), or a hose can be fitted taking the regenerating air to the outside of the engine room. If a hose is fitted discharging the wet air outside, the end of the hose must be carefully fixed and the opening protected against dirt, rain and mechanical damage. Avoid sharp bends & U-bends acting as water locks.

Keep the engine room well-ventilated.

Place the dehumidifiers according to the manufacturers recommendation & protect against possible mechanical damage.

Some dehumidifiers must be fitted with orifices according to the manufacturer’s recommendation.

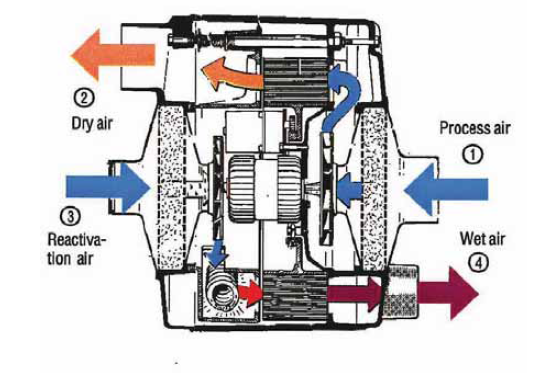

Dehumidifier principle and recommended type

There are mainly two dehumidifier principles:

Absorption type:

- The humid air(process air) is circulated in the closed system through an absorber element which dries the air. The absorber element is continuously turned & in another chamber heated air(regenerating air) is blown through the absorber element in order to remove the water from the absorber element. This type is recommended.

Condenser type:

- The humid air (process air) is passing a condenser, where by cooling the air, the water condensate. The condenser type is not as efficient at low temperature as the absorption type and is not recommended.

The principle of the recommended absorber type dehumidifier

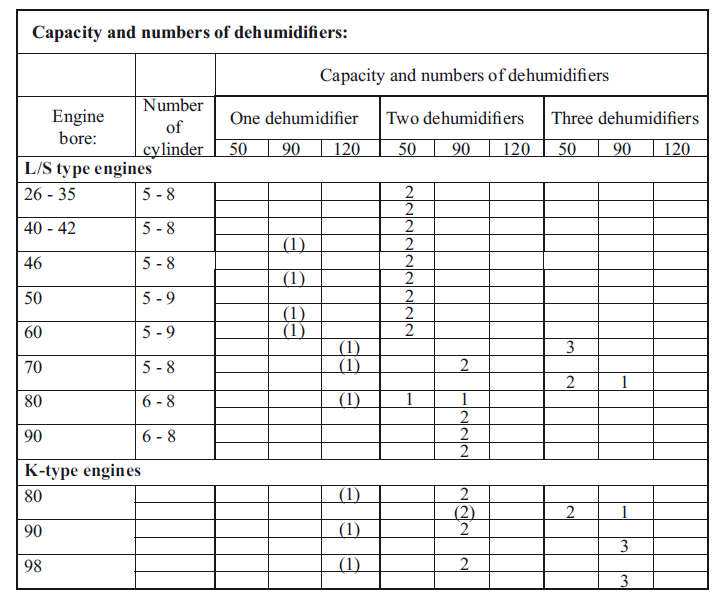

Choosing dehumidifiers

The dehumidifiers must have sufficient capacity to keep the humidity in the engine below 50% RH. The needed capacity of the dehumidifier may vary since the efficiency of the dehumidifier is depending on the ambient temperature and humidity.

When starting the dehumidifiers, the humidity of the air in the engine should be below 50% RH within a maximum of 48 hours. If the humidity of 50% RH is not reached, the system must be investigated and checked if it is connected incorrectly. It is also a possibility that the capacity of the dehumidifiers is insufficient, and it could be necessary to find the proper size of the dehumidifiers by experience.

Note:- Capacity of dehumidifiers deviated air at max. 75% RH. If 95% RH the needed capacity might increase around 50%.

For preliminary estimation of the total capacity & numbers of dehumidifiers, the below table can be used:

Operation of dehumidifier

To obtain a satisfactory result of the dehumidifying process in the engine, the following items must be optimised:

- The engine must be effectively sealed, so the dry air is not lost because of leakage, i.e. venting pipe, inspection covers, manholes & doors must be sealed & closed tight

- The hoses between the engine and the dehumidifiers must be of a good quality and without bends or damages – i.e., the hoses must be shortened, so the lengths of the hoses are as short as possible.

- The hoses must be connected correctly to the dehumidifiers, and the regeneration air must be led away from the engine (out of the engine room). Care should be taken, that condensing water in the wet regenerating pipe will not enter the dehumidifiers.

- The dehumidifiers must be in good order, i.e. fitted with orifice if recommended, clean filters, proper hose connections, correct power connection, placed on the gallery of the engine and protected against mechanical damage.

- The systems must be inspected daily & checked.

- At a daily inspection, the temperature and humidity (and other possible parameters for ensuring correct dehumidifier running) must be measured and recorded. The measurements can be taken from the hose outlet from the engine or by readings from the outlet dummy cover fitted thermometer and hygrometer. If the humidity exceeds 50% RH, the system must be investigated and corrected to ensure proper operation.

- Measuring the humidity can be done by using a portable hygrometer or by using fixed-fitted hygrometers and thermometers in the outlet dummy covers on the engine. It is recommended to use a portable hygrometer, as the correlation for the many measurements and the required calibration of the measuring tools become easier and more accurate. The hygrometers should be calibrated once a month.

- On a monthly basis the hole dehumidifier system should be examined and adjusted to optimal condition, i.e., filters, orifices, electric cables, hoses and the connection of the hoses to engine and dehumidifiers.

- For operation and maintenance of the dehumidifiers, follow the manufacturer’s instructions.

Sketch for connecting dehumidifiers