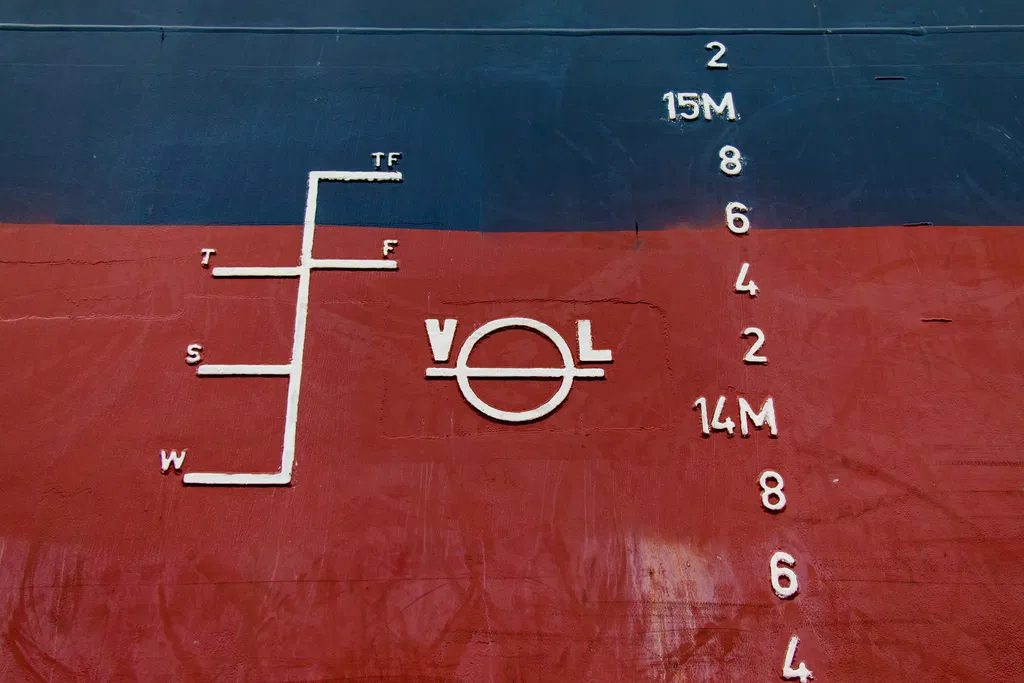

Load Line:- Load line is a special marking amidships which shows the draft of the vessel and the maximum permitted limit in distinct types of waters to which the ship can be loaded.

FREEBOARD:- Freeboard is the distance measured from the waterline to the upper edge of the deck plating at side of the freeboard deck amidships.

In the year 1930, the first International Load Line Convention came in to existence, after which, it was periodically amended until the latest one that happened in 2003.

Freeboard and stability curves are inextricably linked.

With an increase in the freeboard:

- Righting levers (GZ) are increased.

- GMT increases.

- Range of stability increases.

- Deck edge immerses later at greater angle of heel.

- Dynamical stability increases.

- Displacement decreases.

- KB decreases

There are two types of Load line markings:-

- Standard Load Line marking – This load line marking is applicable to all types of vessels.

- Timber Load Line Markings – This load line marking is applicable to vessels carrying timber cargo.

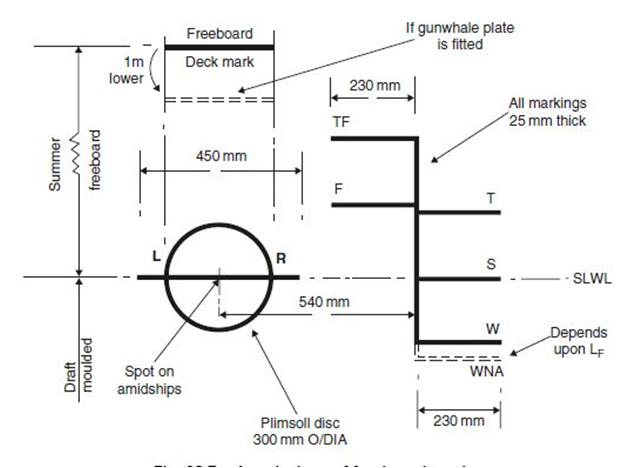

The load lines and freeboard deck line must be painted in white or yellow on a dark background, or in black on a light coloured background. The letters on both side of the load Line disc, indicating the assigning authority, should be 115 mm in height and 75 mm in width.

The complete Load line markings contains 3 vital parts.

- Deck Line – It is a horizontal line which measures 300mm by 25mm. It is passing through the upper surface of the freeboard.

- Load Line Disc – It is the 300mm diameter and 25mm thick round shaped disc. It is intersected by a horizontal line. The upper edge of that horizontal line marks the ‘Summer salt water line’ also known as ‘Plimsol Line’.

- Load Lines – Load lines are horizontal lines expanding forward and aft from a vertical line placed at a distance of 540mm from the centre of the disc. They measure 230mm by 23mm. The upper surface of the load lines indicate the maximum depths to which the ships maybe submerged in different seasons and circumstances.

- S is the Summer watermark for water of 1.025t/m3 density. It is fixed by the Department for Transport (DfT) Tabulated Freeboard values, based on the vessel’s freeboard length and various corrections. Summer watermark is placed at the Summer load water line.

- T is the Tropical watermark and is 1/48 of the Summer load draft above the S mark.

- F is the Fresh watermark. Fresh watermark is W/(4 TPCSW) or 1/48 of the Summer load draft above the S mark. W and TPCSW are values relevant to the Summer load water line.

- TF is the Tropical Fresh watermark and is the (T F) marks above the S mark.

- W is the Winter watermark. It is 1/48 of the Summer load line draft below the S mark.

- WNA is the Winter North Atlantic watermark. It is not painted on the ship sides for a vessel equal to or more than 100 m freeboard length. when the vessel is less than 100 m floodable length, then the WNA is placed 50mm below the W mark.

- classification bodies:

LR- Lloyds Registry based in the UK

AB- American Bureau of Shipping in USA

NV- Norske Veritas in Norway

BV- Bureau Veritas in France

GL- Germanisches Lloyd of Germany

CA- Common wealth of Australia

NK- Nippon Kaiji Kyokai of Japan

- Seasonal allowances depend on Department for Transport DfT World zone map (at rear of their freeboard regulations) and on three factors, these three factors being:

1. Time of year.

2. Geographical location of the ship.

3. LBP(Length Between Perpendicular) of the ship, relative to a demarcation value of 100 m

LOAD LINE CERTIFICATION(5 years)

All vessels must be issued with a load line certificate. The type of the certificate will depend upon the Assigning Authority as follows:

If the certificate issued is an International Load Line Certificate it shall be in the form prescribed by the 1966 Convention which is detailed in the IMO publication ‘Load Lines – 2002 Edition’ .

- If the certificate issued by the assigning authority is an United Kingdom Load Line Certificate(applicable to UK registered ships) it shall be in the form prescribed in Schedule 8 of MSN 1752(M).

Surveys

A vessels will be subjected to the following surveys:

- Initial survey before the ship is put down into service.

- Renewal survey at time period not exceeding five years; Annual survey within 3 months either way of the *anniversary date of the load line certificate. The surveyor will approve the load line certificate on satisfactory completion of the annual survey.

The time period of validity of the load line certificate can be extended for a period not exceeding 3 months or the purpose of allowing the ship to complete its journey to the port in which it is to be surveyed.

PREPARATIONS FOR LOAD LINE SURVEY

1. Check all access openings at ends of enclosed structures are in good conditions. All doors, clamps and hinges to be free and well greased. All gaskets and water tight seals must be crack free. Ensure that the doors open from both sides.

2. Check all cargo hatches and access to holds for weather tightness.

3. Check the efficiency and securing of all the portable beams.

4. If the portable wooden hatch covers are used check that they are in good condition.

5. If the tarpaulins are used at least two should be provided for each hatch and in good condition.

6. Inspect all the machinery space openings on exposed deck.

7. Check that any manholes and flush scuttles are capable to made watertight.

8. Check that all the ventilator openings are provided with efficient weather tight closing appliance.

9. All the air pipe should be provided with satisfactory means for closing and opening.

10. Inspect any cargo ports below the freeboard deck and ensure that all of them are watertight.

11. Ensure that the non return valves on overboard valves are operating in a satisfactory manner.

12. Side scuttles and openings below the freeboard deck should have efficient internal watertight deadlights.

13. Check that all the freeing ports are in satisfactory conditions.

14. All guard-rails and bulwarks must be satisfactory condition. 15. Paint the deck line, load line marks, load line and the draught marks