Q. Referring to various alternatives to tin-based antifouling paints discuss the following:-

A. Hull roughness of different types of the antifouling paints.

B. Enhancement of foul release coatings by the oil incorporations.

C. Personal and health safety during application of antifouling paints.

Answer:-

A. HULL ROUGHNESS OF DIFFERENT TYPES OF ANTI-FOULING PAINTS

a. There are three main categories of tin-free antifouling paints

i. Controlled Depletion Polymer (CDP) paint

- CDP is based on copper.

- It also contains some very strong boosting biocides.

- The biocides are released by the diffusion; the dissolution gradually slows down due to a leached layer formed by the insoluble materials at the surface.

- The roughness of the surface & fuel consumption will therefore increase as the time passes.

- the average hull roughness (AHR) increase of these coatings is estimated at about 40 microns/year

ii. Hybrid TBT free paint

- Hybrid is an antifouling which has the CDP features of surface tolerance & attractive volume solids, control of the biocide release &reduced leached layer size.

- Since CDP & Hybrid antifoulings are not made for more than 36 months in-service on the vertical sides of a vessel, the power/fuel penalty for these products rises sharply after 3 years

- For Hybrid TBT Free antifouling, offers a balance of CDP type & SPC type antifouling properties with performance & AHR increase assumed to be midway between the two at about 30 microns per year.

iii. Self-Polishing Copolymer (SPC) paint

- SPC contains smaller amounts of the biocides than CDP & is also less toxic.

- The base is copper as in CDP, but the amount needed is only 2/3rd to that of CDP.

- The other biocide used in the SPC is normally zinc pyrithione. The function is based upon a chemical reaction with water (hydrolysis).

- SPC has a more controlled leakage of the biocides over time which decreases the risk of fouling.

- For Self-Polishing Copolymer (SPC) antifouling, average increase was found to be significantly less, at about 20 microns increase in AHR per year

iv. Fouling Release paint

- Fouling release is an antifouling paint, which is free from biocides.

- It is normally silicone-based and leaves a non-stick surface.

- The efficacy is dependent on the speed of the vessel as any attached fouling is supposed to wash off.

- For Foul Release antifouling, the AHR increase is assumed to be only 5 microns per year

B. ENHANCEMENTS OF FOUL RELEASE COATINGS BY OIL CORPORATIONS

a. Fouling release coatings have been developed as an alternative to biocide containing paints.

b. They function by minimizing the adhesion strength of attached organisms, which are removed as the vessel moves through the water

c. Oils can enhance properties of foul-release paints.

d. Oils by their nature are lubricants and therefore should decrease the coefficient of friction.

e. It has been found that incorporation of low molecular weight silicone polymers oils can enhance foul-release properties of polymerdimethylsiloxane (PDMS) polymers

f. The method for the enhancement of fouling release performance has been oil incorporation, in which a polymerdimethylsiloxane PDMS oil was incorporated into a silicone matrix.

g. Previous research suggested that incorporation of foul release PDMS oil reduced total coverage and might enhance ease of removal of fouling.

h. Foul release coatings on the underwater hulls and propellers of ships are a revolutionary new way to improve efficiency.

i. They not only provide improved environmental control, since they do not use biocides to prevent fouling, but they have also been proven to provide better fouling control than SPC antifouling.

j. These result in increased fuel efficiency, reduced engine spare parts and reduced maintenance costs.

k. The addition of oil to a PDMS coating further decreases the adhesion of barnacles and certain species of oysters.

l. The environmental impact of these coatings is minimal since oil does not significantly deplete from the coating

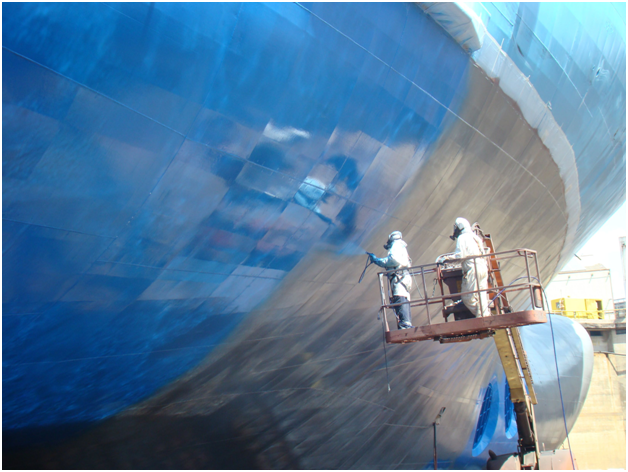

C. PERSONNEL AND HEALTH SAFETY DURING APPLICATION OF ANTI-FOULING PAINTS

a. The paints are toxic and can harm personal health as well as marine environment

b. Contact with anti-fouling paint can irritate skin, eyes and even permanently damage your health

c. Thus when applying this paint person should wear the full PPE such as goggles, full body coveralls, covered shoes and chemical resistant gloves

d. Respiratory protective equipment should be worn where the paint applied in areas of poor ventilation

e. Applying anti-fouling paint personnel must set up a controlled work area thus prevent paint leaving the area environment or coming in contact with neighboring bystanders

f. Spray painting and anti-fouling maintenance should be done in calm weather. This will decrease the chance of your activity impacting other people or the environment