Q. Explain latest developments in Marine “Tribology”. Explain the inferences you may draw from a main engine lub oil analysis report with the proposed corrective action in each case.

Answer:-

Tribology is the science & engineering of the interacting surfaces in relative motion. It includes the study & application of the principles of

1. Friction

2. Lubrication

3. Wear

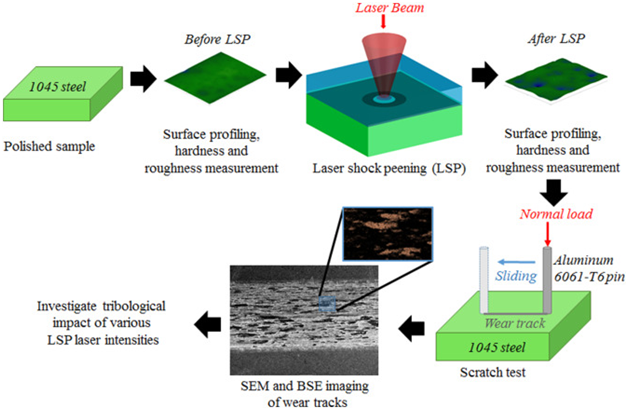

- The tribological interactions of a solid surface’s exposed face with interfacing materials and environment may result in loss of material from the surface. The process leading to the loss of material is called “wear”. Major types of the wear include abrasion, friction (adhesion & cohesion), erosion, & corrosion.

- Wear can be minimized by modifying the surface properties of solids by one or more of “surface engineering” processes (also called surface finishing) or by use of lubricants (for frictional or adhesive wear)

- There are world’s two biggest manufacturers of large marine diesel engines, MAN B&W and Wartsila .

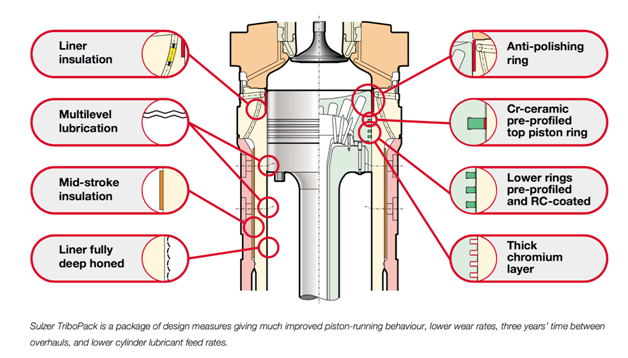

- Sulzer RTA-series engines now incorporate TriboPack technology -a package of design measures that enable the TBO of the cylinder components, including piston ring renewal, to be extended to at least three years. At the same time, TriboPack permits the further reduction of the cylinder lubricating oil feed rate.

The design measures incorporated in Tribo Pack are:

1. Multi-level cylinder lubrication

2. Liner of the suitable material, with sufficient hard phase

3. Careful turning of the liner running surface & deep-honing of the liner over the full length of the running surface

4. Mid-stroke liner insulation, & where required, insulating tubes in the cooling bores in the upper part of the liner

5. Pre-profiled piston rings in all the piston grooves

6. Chromium-ceramic coating on the top piston ring

7. RC (Running-in Coating) piston rings in all the lower piston grooves

8. Anti-Polishing Ring (APR) at top of the cylinder liner

9. Increased thickness of the chromium layer in the piston-ring grooves.

- A key element of Tribo Pack is the deep-honed liner. Careful machining & deep honing gives the liner an ideal running surface for the piston rings, together with an required surface microstructure.

- The Anti-Polishing Ring prevents the buildup of deposits on the top land of the piston which can damage the oil film on the liner and cause bore polishing.

- It is also important that the liner wall temperature is adapted to keep the liner surface above the dew point temperature throughout the piston stroke to avoid cold corrosion. Mid-stroke insulation and, where required, insulating tubes are therefore utilized to optimize liner temperatures over the piston stroke.

Other development

1. Alpha lubrication (MAN)

- Electronically controlled cylinder lubrication.

- The lube oil is injected exactly when the piston ring pack is passing the lube oil quills, thus ensuring the best possible utilization of the costly lube oil.

2. Anti-polishing ring.

- Piston ring:-CPR, Gas tight lock and controlled leakage grooves.

3. New tie rod design (MAN)

4. Development in Bearing design

- Increase in bearing area

- Shape changed( lemon shaped)MAN

- Bearing temperature monitoring for moving bearing

- On line bearing wear measurement.

- Thick shell-Flex edge design(MAN)

- Thin shell-Blend edge design