Out of the total operational costs of a ship, fuel costs account for by far the highest proportion. In view of the global economic situation and the rising oil prices, shipowners and charterers are looking for solutions to cut costs by reducing fuel consumption. Low load operation, also well-known as “slow steaming”, represents the currently most effective and popular measure to cut fuel costs and, in consequence, the total operational costs for increased competitiveness in the market.

Low load operation down to 10-20% MCR is possible with MAN B&W engines and there is an increasing trend to operate in these very low engine load ranges. As the engines were not designed for this operational

profile, various retrofit modifications to the engine can compensate for this.

Benefits from slow-steaming upgrades

Apart from running at part-load, there are a number of ways to further increase the financial benefit from slow steaming. These measures enable reductions in fuel and lubricating oil as well as an improved engine

performance, adding significant further gains to the annual savings achieved by slow steaming itself.

Such solutions are:

– Turbocharger cut-out

– Slide fuel valves

– Alpha Lubricator upgrades

– Engine derating with the option of new propeller

design.

Turbocharger Cut-Out

The big money saver for low load operation

Benefits for slow-steaming operation

– Substantial SFOC savings at low load

– Flexible solution allowing both low and full load.

Operating principle

Reducing speed is the most effective measure to reduce fuel costs. However, at low load, the turbochargers are operating below their optimal range. This has an adverse effect on their running performance, which limits the potential fuel oil savings. On engines with two or more turbochargers, this can be overcome by installing a turbocharger cut-out. Thereby, the performance of the remaining turbocharger(s) will be improved from running at higher revolutions, which again reduces the fuel oil consumption further. The solution with swing gates offered by MAN Prime-Serv gives the operator the option of disengaging one

of the turbochargers for low load operation whenever

needed. This flexibility allows optimised turbocharger

efficiency at both part and full load.

Reception in the shipping world

The solution has been widely accepted in the shipping world and has become a standard retrofit choice for many larger vessels with three and four turbochargers. Lately, service experience has shown good SFOC

savings for engines equipped with two turbochargers, and turbocharger cut-out is expected to be an attractive upgrade for them as well.

Fuel oil savings potential

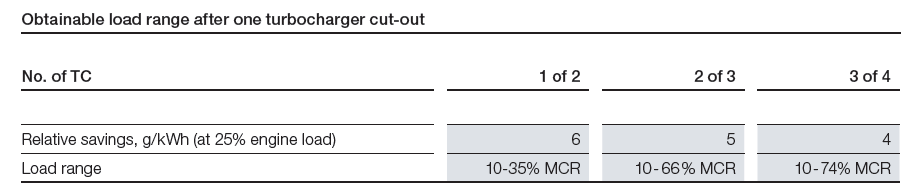

Depending on how the individual engine was designed, substantial SFOC savings can be achieved by installing a turbocharger cut-out. The relative savings stated below are based on the latest experience from engines in service and should be seen as a guideline.

Slide Fuel Valves

Eliminating deposits when slow-steaming

Benefits of slow-steaming operation

The slide type fuel valve is the latest design and is a must-have for slow-steaming operation. Reducing the vessel speed reduces fuel costs, but slide valves are a necessity for proper large-scale slow-steaming operation. The slide type design improves the combustion process and eliminates the carbon deposits in the exhaust gas ways that typically occur from low

load operation with the traditional fuel valves. Such deposits accumulate rapidly, and engines with traditional fuel valves will require more maintenance and frequent cleaning of the gas ways.

– Improved low load performance

– Better combustion process

– Reduced fouling of gas ways and exhaust gas boiler

– Reduced fouling of piston top land.

Operating principle

The slide fuel valve reduces the amount of soot and gives better combustion properties. This is achieved with a more advanced design that eliminates the sac volume in the past types. The spray pattern of the fuel is also further optimised leading to an improved and more complete combustion process. This results in less deposits throughout the gas ways and a reduction in overall emissions. The visible smoke level is also greatly reduced as a result of the improved combustion. The need for maintenance is reduced with the cleaner gas ways, and testing procedures are simpler thanks to the improved design.

Reception in the shipping world

Slide fuel valves are now standard on new MAN B&W engines but are also considered a must-have among most shipowners and operators for older engines.

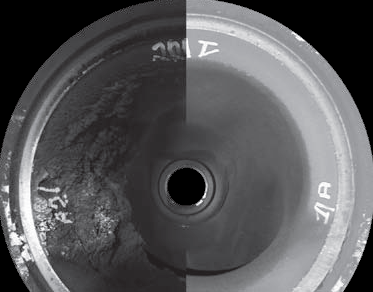

Cleaner exhaust gas ways

The two photographs illustrate a key benefit of retrofitting the slide fuel valve. The first photo shows an exhaust valve bottom piece with substantial deposits caused by an incomplete combustion process. The right-hand side of the photo shows the same valve seat after the slide fuel valve has been installed. The photo was taken after 890 running hours with the new

slide fuel valve. No additional cleaning or scraping was done when retrofitting the new type of fuel valve.

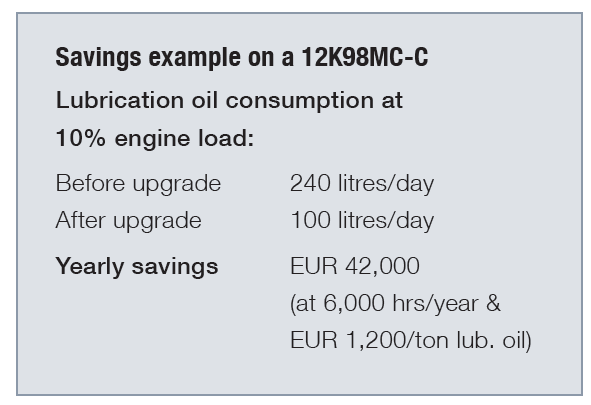

Alpha Lubricator Upgrade

Lube oil savings from slow-steaming

Benefits of slow-steaming operation

– 20-50% cylinder lubrication oil savings at low load

– More accurate feed rate control at all engine loads

– Minimising over-lubrication at low load, reducing deposits, hence improving the cylinder condition.

Operating principle

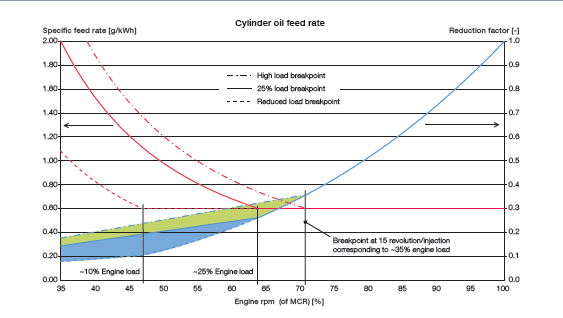

In 2012, a new layout of the Alpha Lubricator in new MC engines has been introduced. Along with a number of design improvements, the injection volume and frequency has been changed in order to optimise the cylinder oil consumption at low load. Now, the Alpha Lubricator upgrade is introduced as a retrofit solution, optimising cylinder oil consumption in engines in service. A consequence of substantial over-lubrication at low

load is generating deposits on the piston crown and rings, increasing the risk of damage to the cylinder liners. In addition, over-lubrication generates excess costs for unnecessary lubrication oil. The Alpha Lubricator upgrade is a major improvement of the system. By adapting the new lubricator layout, a complete lubrication optimization at all engine loads is now possible. The new lubricator layout reduces the engine power level at which the algorithm, controlling the cylinder oil feed rate, changes. The “break point” is moved to the left. The Alpha Lubricator upgrade enables the cylinder oil feed rate to follow a lower curve. The marked area in the figure above corresponds to the potential lubrication oil savings from upgrading the system.

Scope of delivery

The Alpha Lubricator upgrade comprises a new MCU, the latest software, and new improved lubricators either as complete lubricators or as kits, which can be used for newer unworn units.

Derating

Changing engine rating

Vessels designed around 2008 were designed for high service speeds. Many of these vessels are now becoming increasingly uneconomical in today’s slow steaming market. Derating offers the possibility of changing the specified maximum continuous rating (SMCR) to match the requirements of vessels expected to remain slow steaming.

Benefits

-Reduced SFOC at all loads

– New refurbished turbocharger

– Reduced power consumption (propeller exchanged).

Principle

Derating is the procedure of changing the rating (power and speed) of an engine. Choosing the optimum engine rating (or layout) is today, as standard, performed on new buildings in order to ensure that the required vessel speed is reached by an optimum combination of propeller and engine layout. In retrofit applications, derating is offered to ensure that the

engine rating (layout) is changed to meet the current ship speeds in today’s slow steaming market. Changing the SMCR of an already built engine (derating) permanently changes the performance of the engine

by limiting the power output and thereby the vessel’s maximum speed.

Engine modifications

Derating will involve changing/modifying the below

main engine components:

– Fuel and exhaust cam positions (timing) & size

– Fuel atomizers

– Fuel valves (slide fuel valves must be installed)

– Shim’s height between x-head and piston rod

– Wave cut of cylinder liner (removal of wear edge)

– Re-matching turbocharger(s)

– New technical file

– NOX measurements on board for parent vessels.

Operational profile

The main prerequisite for a successful derating project is a thorough investigation in which the expected future operational profile of the vessel is analysed.

– Maximum ship speed, after modification

– Design speed, after modification

– Operational speed distribution by running hours.

The benefit of any derating project is critically dependent on the quality of the operational profile.

Propeller exchange

Derating often includes an exchange of the original propeller with a new propeller with an increased diameter optimized for the revised engine layout with reduced engine speed (rpm). Typically, combining engine derating with an exchange of the existing propeller will have

a positive influence on the project payback time when compared to derating the main engine alone.

REFRENCE-MANDieselTurbo.com/PrimeServEarth